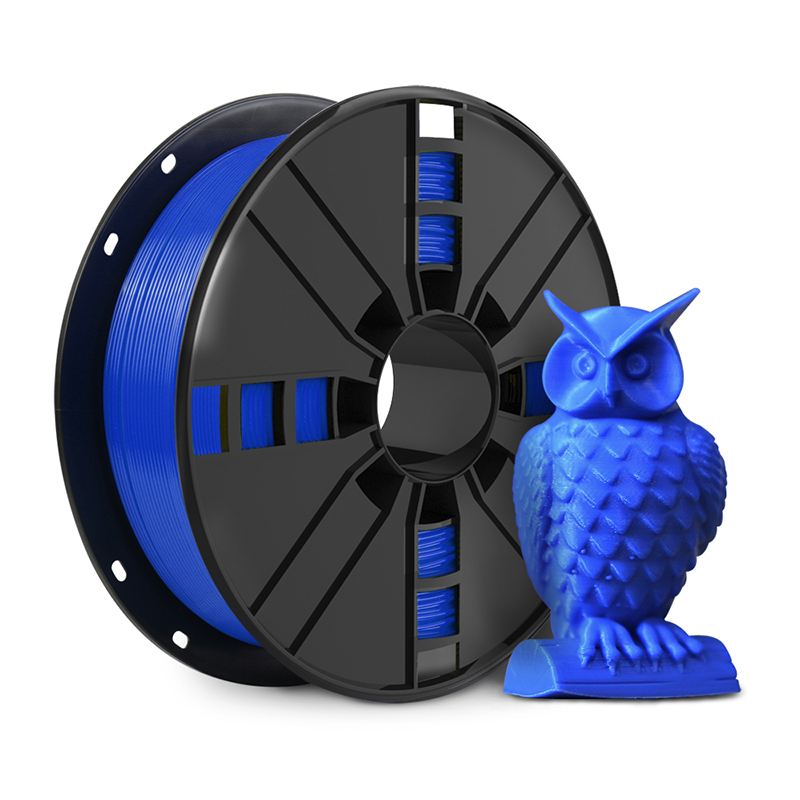

1.75mm PLA filament blue color

Product Features

| Brand | Torwell |

| Material | Standard PLA (NatureWorks 4032D / Total-Corbion LX575) |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.02mm |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctnsealed plastic bag with desiccants |

More Colors

Color Available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Nature, |

| Other color | Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent |

| Fluorescent series | Fluorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue |

| Luminous series | Luminous Green, Luminous Blue |

| Color changing series | Blue green to yellow green, Blue to white, Purple to Pink, Grey to White |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll 1.75mm PLA filament with desiccant in vaccum package

Each spool in individual box (Torwell box, Neutral box, or Customized box avilable)

8boxes per carton (carton size 44x44x19cm)

Our advantages

a).Manufacturer, in filament and reference products, competitive price.

b).10 years’ of experience working with OEM's various materials.

c). QC:100% inspection.

d).Confirm sample: before start mass production we will send the pre-production samples to customer for confirmation. We will modify the mould until customer satisfied.

e). Small Order Allowed.

f). Strict QC and high quality.

g). Highly skilled manufacturing process.

h). A broad variety of OEM product range.

| Density | 1.24 g/cm3 |

| Melt Flow Index(g/10min) | 3.5(190℃/2.16kg) |

| Heat Distortion Temp | 53℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 11.8% |

| Flexural Strength | 90 MPa |

| Flexural Modulus | 1915 MPa |

| IZOD Impact Strength | 5.4kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

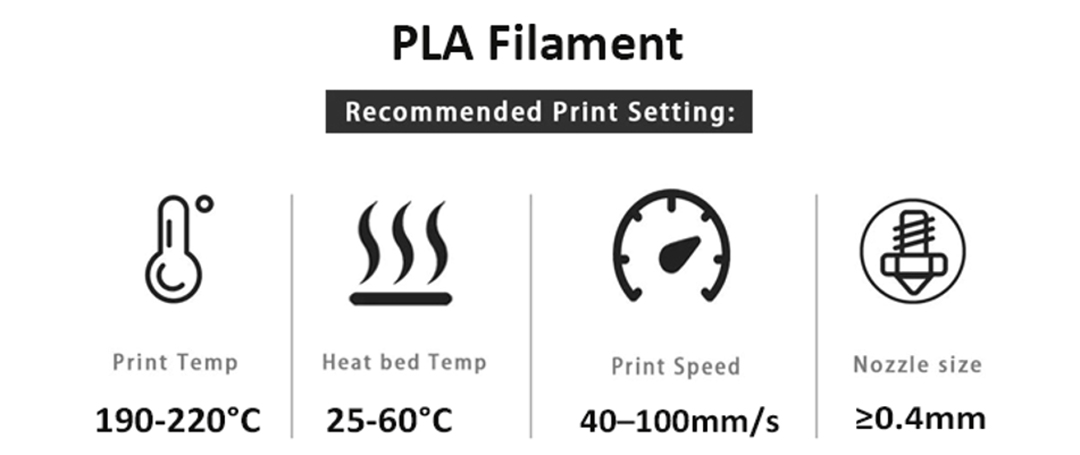

| Extruder Temperature(℃) | 190 – 220℃Recommended 215℃ |

| Bed temperature(℃) | 25 – 60°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | On 100% |

| Printing Speed | 40 – 100mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |

Write your message here and send it to us