ABS Filament for 3D prinitng 3D printing materials

Product Features

Acrylonitrile butadiene styrene (ABS) is one of the most popular 3D printer filaments on the market.

ABS is more difficult to process than normal PLA, while it is superior in material properties to PLA. ABS products are characterized by high durability and high-temperature resistance. It requires a higher processing temperature and a heated bed. The material tends to warp without adequate heat.

ABS provides excellent quality finishes when handled properly, which by itself is a challenge for many. It’s also suitable for use in relatively high-temperature applications, for example creating 3D printer parts.

| Brand | Torwell |

| Material | QiMei PA747 |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 410m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 70˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV, SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

More Colors

Color Available

| Basic color | White, Black, Red, Blue, Yellow, Green, Nature, |

| Other color | Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent |

| Fluorescent series | Fluorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue |

| Luminous series | Luminous Green, Luminous Blue |

| Color changing series | Blue green to yellow green, Blue to white, Purple to Pink, Grey to White |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll ABS filament with desiccant in vaccum package

Each spool in individual box (Torwell box, Neutral box, or Customized box avilable)

8boxes per carton (carton size 44x44x19cm)

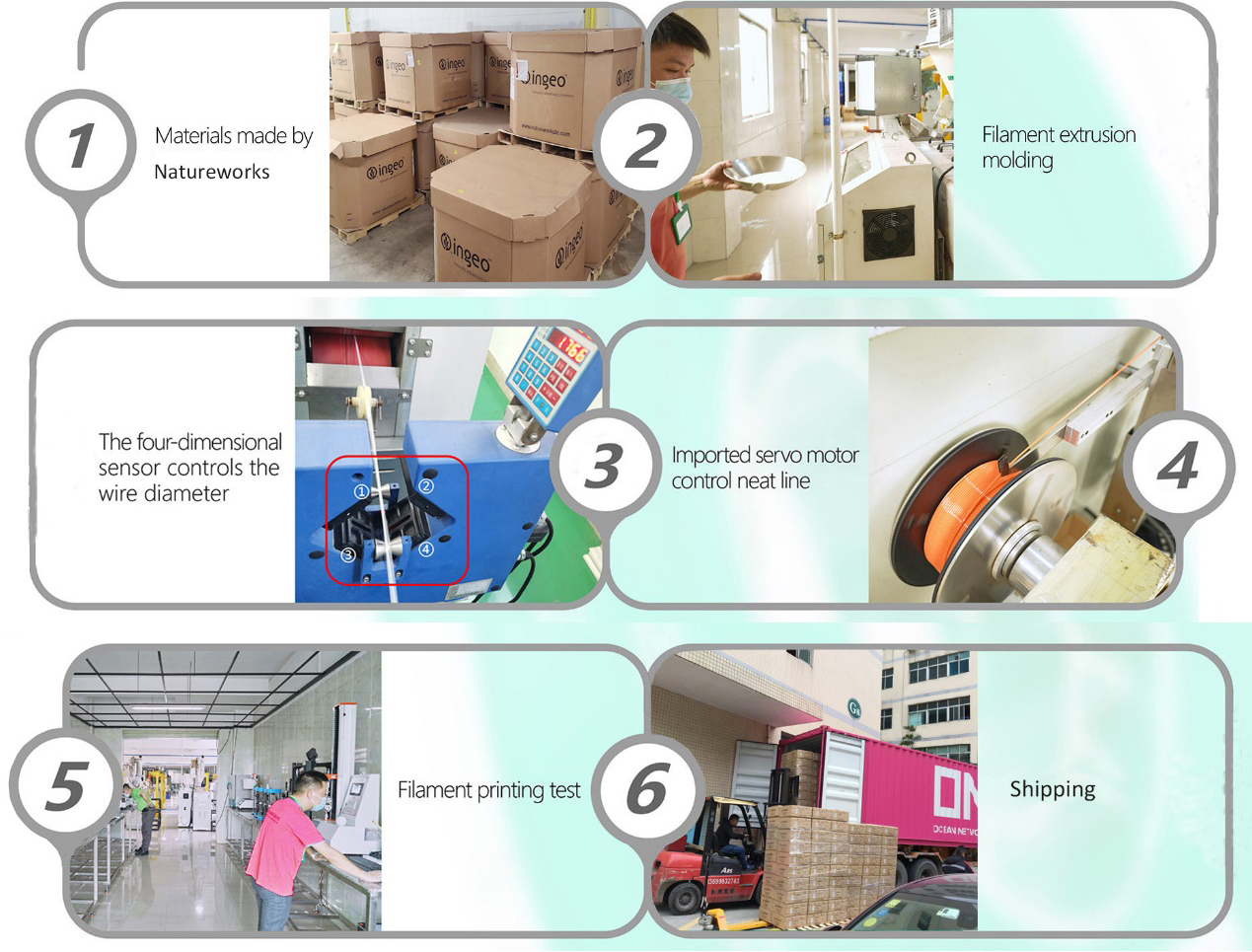

Factory Facility

Tips for printing ABS filament

1. Enclossure used.

ABS is quite sensitive to temperature differences than other materials, using a enclosure will keep the temperature constant, also can keeps dust or debris away from the print.

2. Turen off the fan

Since If a layer is cooled down too fast, it will be easy warping.

3. Higher temperature and slow speed

Print speed below 20 mm/s for the first few layers will make the filament stick on the print bed very well. The higher temperature and slow speed lead to better layer adhesion. Speed can be increased after the layers build up.

4. Keep it dry

ABS is a hygroscopic material, which can absorb moisture in the air. Using plastic vacuum bags when you are not use it. Or use a dry boxes to store.

ABS Filament Advantages

- Good mechanical properties: The material is known to be strong, tough, and durable. It offers good resistance to heat, electricity, and everyday chemicals. ABS is a bit flexible and therefore less brittle than PLA. Try it yourself: Move a strand of ABS filament and it will distort and bend before breaking, while PLA will break much more easily.

- Easy to post-process: ABS is much easier to file and sand than PLA. It can also be post-processed with acetone vapor, which completely removes all layer lines and provides a clean smooth surface finish.

- Cheap: It’s one of the cheapest filaments. ABS offers a great value considering its superior mechanical properties, but be aware of the quality of the filament.

FAQ

A: the material is made with fully automated equipment, and the machine automatically winds the wire. generally, there will be no winding problems.

A: our material will be baked before production to prevent the formation of bubbles .

A: the wire diameter is 1.75mm and 3mm, there are 15 colors, and also can do customize color you want if there are big order.

A: we will vacuum process the materials to place the consumables to be damp, and then put them in the carton box to protection damage during transportation.

A: we use high quality raw materials for processing and production, we not use recycled material, nozzle materials and secondary processing material, and the quality is guaranteed.

A: yes, we do business in every corner of the world , please contact us for detailed delivery charges.

Why Choose Us?

Contact with us via email info@torwell3d.com or whatsapp +86 13798511527.

Our sales will feedback toy our within 12 hours.

|

Density |

1.04 g/cm3 |

|

Melt Flow Index(g/10min) |

12(220℃/10kg) |

|

Heat Distortion Temp |

77℃, 0.45MPa |

|

Tensile Strength |

45 MPa |

|

Elongation at Break |

42% |

|

Flexural Strength |

66.5MPa |

|

Flexural Modulus |

1190 MPa |

|

IZOD Impact Strength |

30kJ/㎡ |

|

Durability |

8/10 |

|

Printability |

7/10 |

|

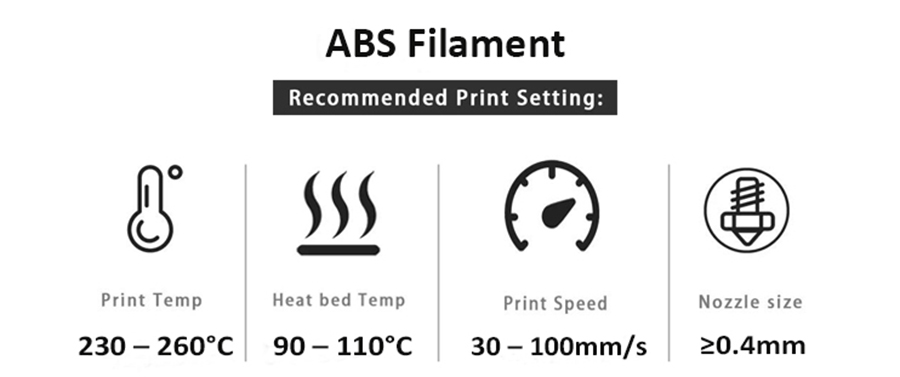

Extruder Temperature(℃) |

230 – 260℃ Recommended 240℃ |

|

Bed temperature(℃) |

90 – 110°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

LOW for better surface quality / OFF for better strength |

|

Printing Speed |

30 – 100mm/s |

|

Heated Bed |

Required |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |