Dual Color Silk PLA 3D Filament, Pearlescent 1.75mm, Coextrusion Rainbow

Product Features

Torwell Dual Color Coextrusion Filament

Different from normal color change rainbow PLA filament, every inch of this magic 3d filament is made of dual colors. Therefore, you will easily get all colors, even for very small prints.

Exquisite Details Smooth and Glossy

The reason why this 3D printer filament looks beautiful is the wonderful silk PLA filament surface.

| Brand | Torwell |

| Material | polymer composites Pearlescent PLA (NatureWorks 4032D |

| Diameter | 1.75mm |

| Net weight | 1Kg/spool; 250g/spool; 500g/spool; |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 325m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctnsealed plastic bag with desiccants |

More Colors

Color available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Silver, Grey, Gold, Orange, Pink |

|

Accept Customer PMS Color |

|

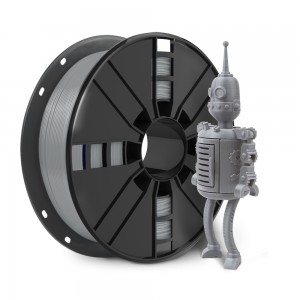

Model Show

Package

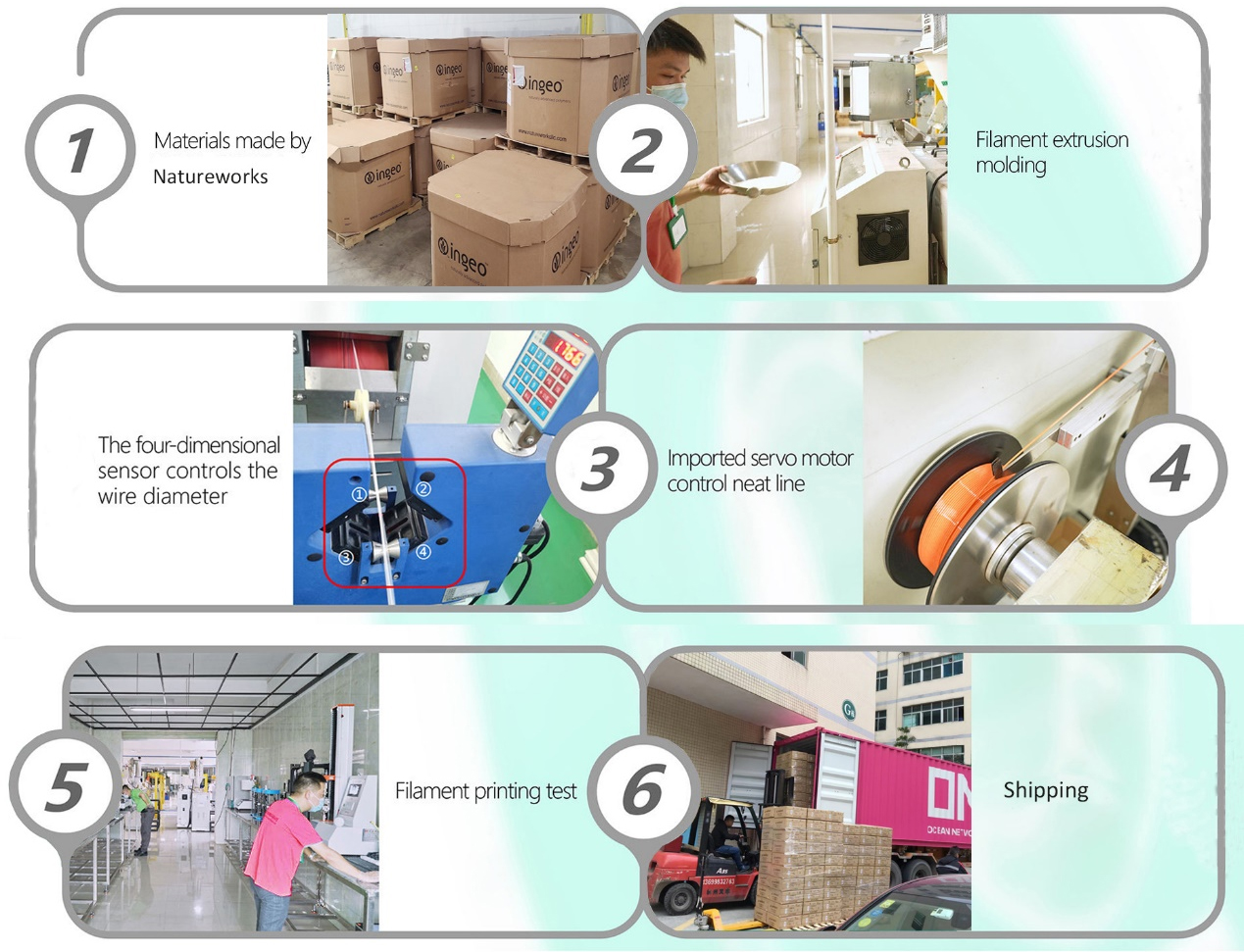

Factory Facility

Torwell, an excellent manufacturer with more than 10years experiences on 3D printing filament.

NOTE

• Keep the filament as vertical as possible without twisting it.

• Because of shooting light or display resolution, there are a little color shading between the pictures and filaments.

• There is a little difference between different batches, so that it is recommended to buy enough filament at one time.

FAQ

A: Confirm the platform has been leveled, the distance between the nozzle and the surface of the platform is appropriate, so that the wire coming out of the nozzle is slightly squeezed.

B: Check the printing temperature and the temperature setting of the hot bed. The recommended printing temperature is 190-220°C, and the hot bed temperature is 40°C.

C: The surface of the platform needs cleaning or you can use special surface, glue, hairspray etc.

D: The adhesion of the first layer is poor, which can be improved by increasing the extrusion line width of the first layer and reducing the printing speed.

A: The toughness of silk pla is lower than PLA, because of the different formula.

B: You can increase the temperature and the number of outer walls to have a better layer adhesion.

C. keep the filament dry to avoid break.

A: Too high temperature can increase the fluidity of the filament after melting, we suggest to reduce the temperature to reduce stringing.

B: You can find the best retraction distance and retraction speed by printing stringing test.

A: Be sure to insert the free end of silk pla filament into the holes to avoid being tangle next time.

A: Please make sure the filament is stored in a sealed bag or box after each print to prevent moisture.

B: If the filament already soaked moisture, dry it in the oven 4 – 6 hours at 40-45°C.

| Density | 1.25 g/cm3 |

| Melt Flow Index(g/10min) | 11.3(190℃/2.16kg) |

| Heat Distortion Temp | 55℃, 0.45MPa |

| Tensile Strength | 57 MPa |

| Elongation at Break | 21.5% |

| Flexural Strength | 78 MPa |

| Flexural Modulus | 2700 MPa |

| IZOD Impact Strength | 6.3kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

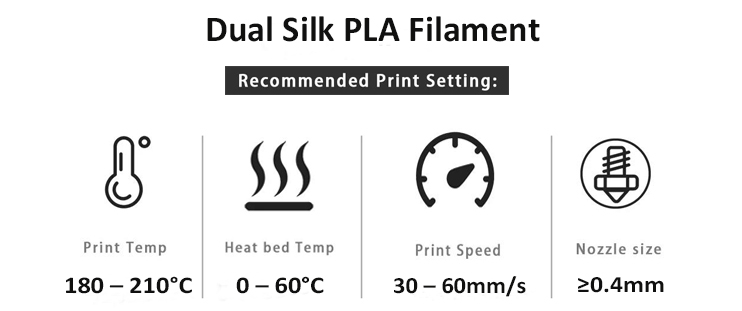

| Extruder Temperature(℃) | 190 – 220℃Recommended≤200℃get better gloss |

| Bed temperature(℃) | 0 – 60°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | On 100% |

| Printing Speed | 30 – 60mm/s; 25-45mm/s for complex object, 45-60mm/s for easy object |

| Layer Height | 0.2mm |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |