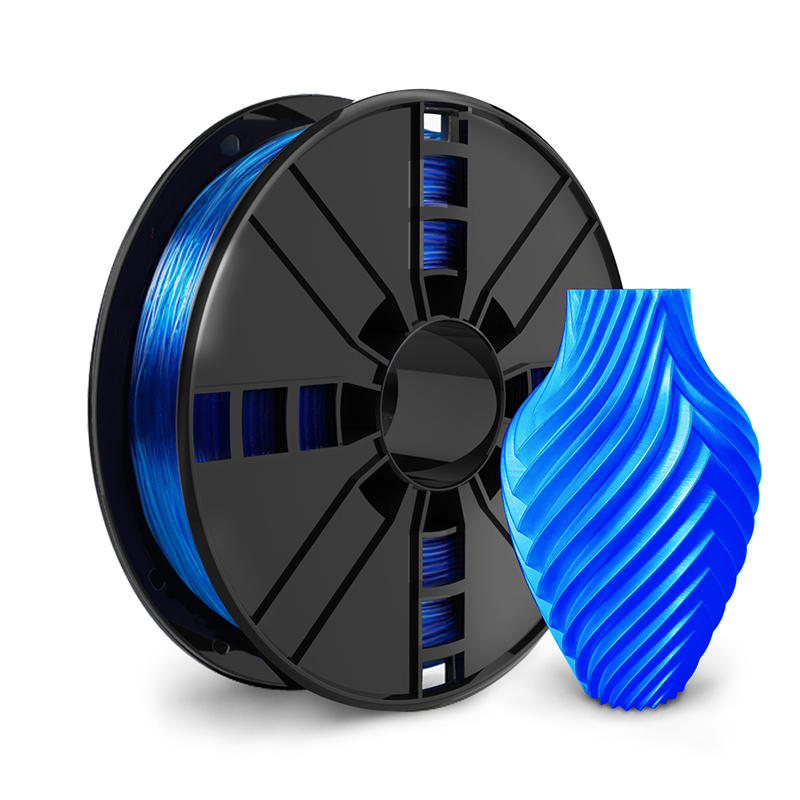

Flexible 3D filament TPU blue 1.75mm Shore A 95

Product Features

| Brand | Torwell |

| Material | Premium grade Thermoplastic Polyurethane |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.05mm |

| Length | 1.75mm(1kg) = 330m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 65˚C for 8h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

Torwell TPU filament is featured by its high strength and flexibility, like a hybrid of plastic and rubber.

95A TPU has high abrasion resistance and low compression compared to rubber parts, especially at higher infill.

In comparison with most common filaments like PLA and ABS, TPU must be run much slower.

More Colors

Color Available

| Basic color | White, Black, Red, Blue, Yellow, Green, Grey, Orange, Transparent |

|

Accept Customer PMS Colo |

|

Model Show

Package

1kg roll 3D filament TPU with desiccant in vacuum package

Each spool in individual box (Torwell box, Neutral box, or Customized box available)

8boxes per carton (carton size 44x44x19cm)

Recommended for printers with direct drive extruder, 0.4~0.8mm Nozzles.

With Bowden extruder you might pay more attention to these tips:

- Print slow 20-40 mm/s Printing speed

- First layer settings. (Height 100% Width 150% speed 50% e.g.)

- Retraction disabled. This would reduce messy, stringing or oozing printing result.

- Increase Multiplier (Optional). set to 1.1 would help the filament bond well. - Cooling fan on after first layer.

If you are having problems printing with soft filaments, firstly, and most importantly, slow the print down, run at 20mm/s will work perfectly.

It is important when loading the filament to allow it to only just start extruding. Once you see the filament coming out the nozzle hit stop. The load feature pushes filament through quicker than a normal print and this can cause it to get caught in the extruder gear.

Also feed the filament direct to the extruder, not through the feeder tube. This reduces the drag on the filament which can cause the gear to slip on the filament.

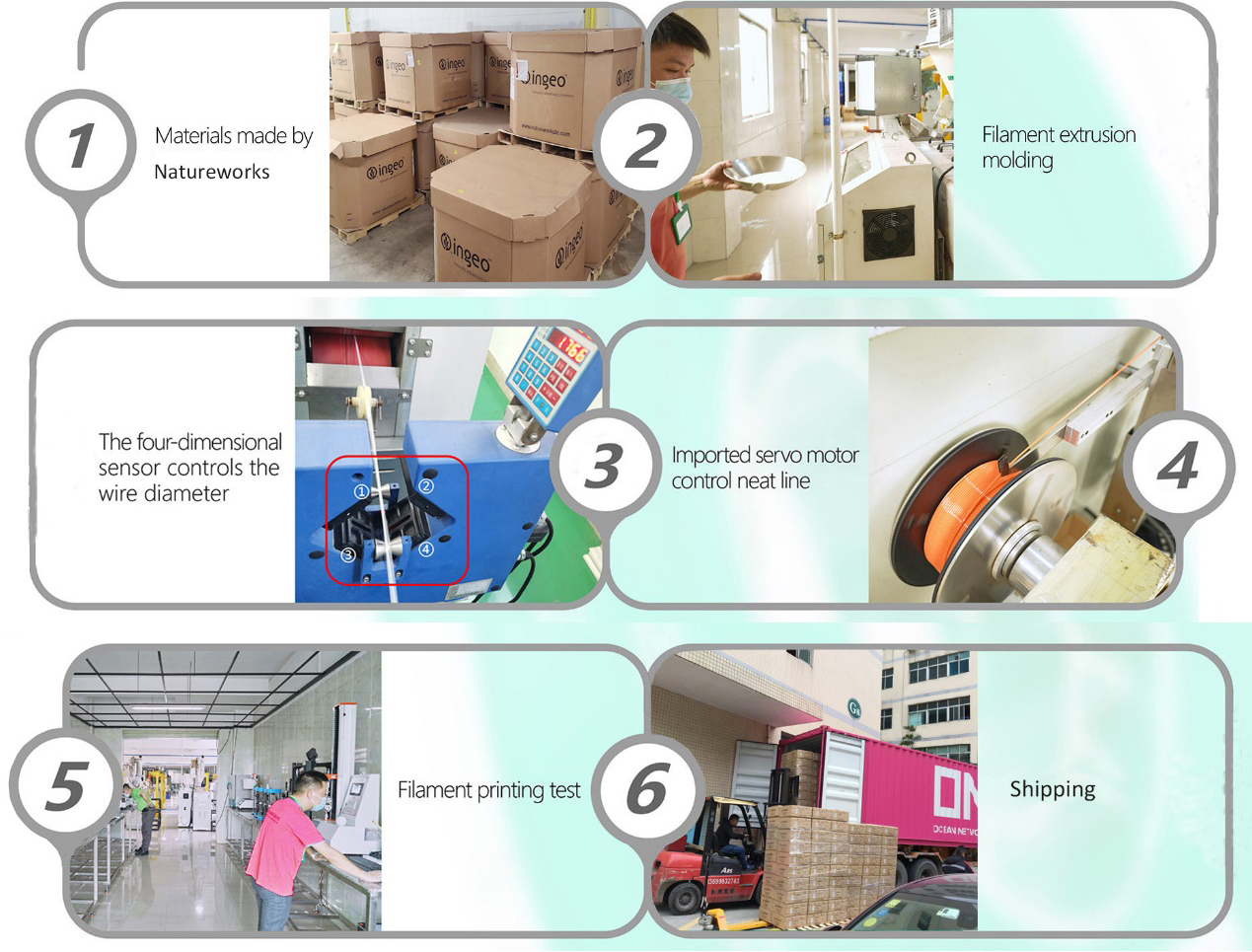

Factory Facility

FAQ

A: Yes, any TPU material can be painted. I use "Tulip Colorshot Fabric Spray Paint". It adheres to the TPU part well and does not rub off on your hands or clothes. Drys in about an hour or less. I also use a heat gun as well to get it to dry in a few minutes. You can use a blow dryer also. You can select a grey TPU filament as a neutral color, then paint it with the paint above in any variety of colors they provide. That's what I do and it works just fine.

A: The TPU got from Torwell has much less odor than PLA. It has no odor that I've noticed at all yet and I run the printer open when I use Flex. As far as toxicity I don't know, but the smell is a non-issue.

A: TPU does better than PLA whenever flexibility is concerned. TPU offers high durability and great impact resistance. PLA is preferred than TPU when ease of printing is a preference, to get objects with strength and better surface quality. TPU can be used in functional parts as an application.

A: Yes, TPU is a heat-resistant filament having a glass transition temperature of 60 DegC. The melting temperature of TPU is higher than PLA.

A: The print speed for TPU filament varies between 15-30 millimeter per second without compromising on quality.

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 1.5(190℃/2.16kg) |

| Shore Hardness | 95A |

| Tensile Strength | 32 MPa |

| Elongation at Break | 800% |

| Flexural Strength | / |

| Flexural Modulus | / |

| IZOD Impact Strength | / |

| Durability | 9/10 |

| Printability | 6/10 |

|

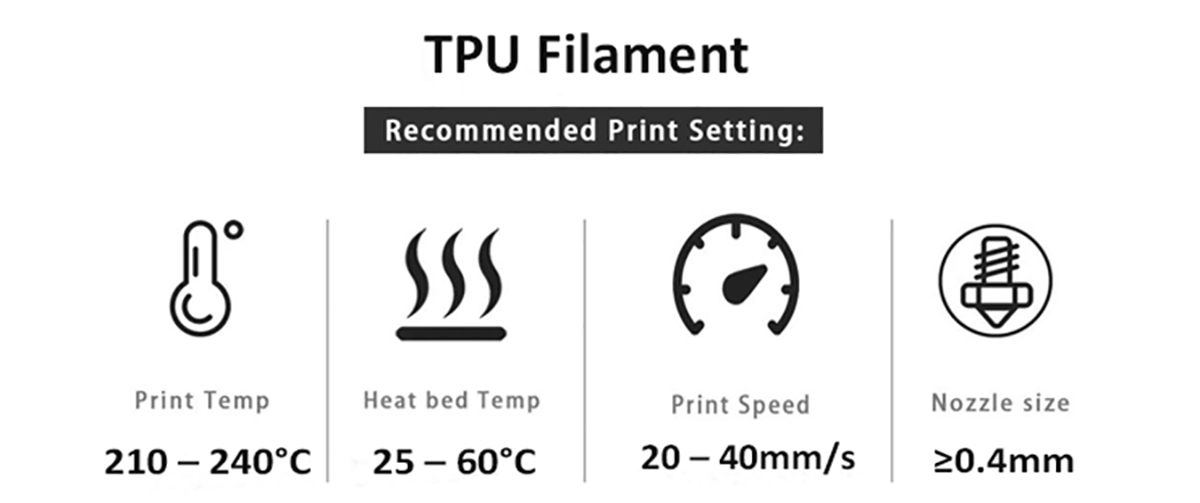

Extruder Temperature(℃) |

210 – 240℃ Recommended 235℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

20 – 40mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |