1.75mm 1kg Gold PLA 3D Printer Filament

Torwell 3D PLA printer filaments are developed especially for our daily printing. Whenever we are printing home decorations, toys & games, households, fashions, prototypes, or basic tools, Torwell PLA is always on top of the list as its consistent quality and rich colors.

| Brand | Torwell |

| Material | Standard PLA (NatureWorks 4032D / Total-Corbion LX575) |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.02mm |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

More Colors

Color Available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Nature, |

| Other color | Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent |

| Fluorescent series | Fluorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue |

| Luminous series | Luminous Green, Luminous Blue |

| Color changing series | Blue green to yellow green, Blue to white, Purple to Pink, Grey to White |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll PLA 3D Printer Filament 1kg with desiccant in vaccum package.

Each spool in individual box (Torwell box, Neutral box, or Customized box avilable).

8boxes per carton (carton size 44x44x19cm).

Tips

- Please insert the filament into the side holes after use to avoid tangles;

- Please store the 3D printer filament in a sealed bag or box after using it.

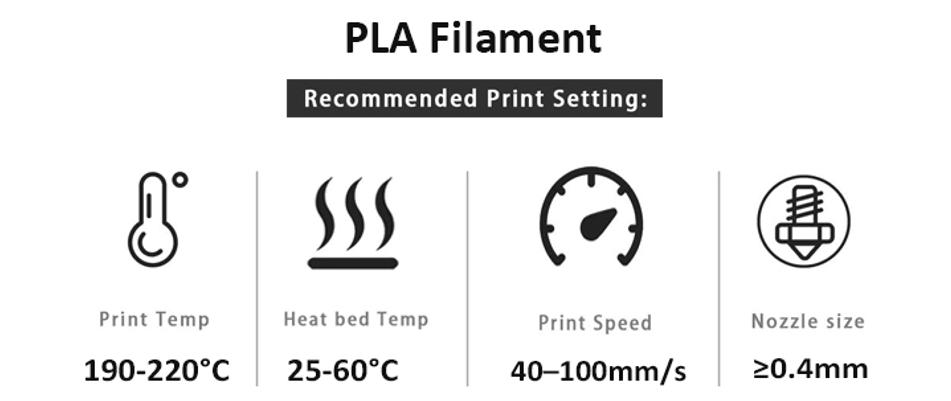

Printer Settings

- Speed: 10-20 mm/s 1st layer, 20-80 mm/s rest of part.

- Nozzle Set-point: 190-220C (hottest on 1st layer for best adhesion).

- Nozzle Actual: maintain set-point, reduce speed if less than.

- Nozzle Type: Standard or wear-resistant for extended use.

- Nozzle Diameter: 0.6mm or larger preferred, 0.4mm okay with 0.25mm minimum for experts.

- Layer thickness: 0.15-0.20mm recommended for a balance of quality, reliability, and productivity.

- Bed Temperature: 25-60C (over 60C can worsen warp).

- Bed Preparation: Elmers purple disappearing glue stick or your other favorite PLA surface preparation.

Why doesn't the filament stick to the build bed easily?

- Temperature: Please check the temperature (bed and nozzle) settings before printing and set it suitable;

- Leveling: Please check if the bed is level, make sure the nozzle doesn't too far or too close to the bed;

- Speed: Please check if the printing speed of the first layer is too fast.

FAQ

A: The wire diameter is 1.75mm, 2.85mm and 3mm, there are 34 colors, and also can do customize color.

A: We use high quality raw materials for processing and production, we not use recycled material, nozzle materials and secondary processing material, and the quality is guaranteed.

A: Our factory is located in shenzhen City, China. Welcome to visit our factory.

A: We can provide you free sample for test, but customer pay the shipping cost.

A: Based on factory original box, original design on product with neutral label, original package for export carton. Custom-made is OK.

A: Ⅰ. For LCL cargos, we arrange reliable logistics company to drive them to the forwarder agent’s warehouse.

Ⅱ. For FLC cargos, the container directly go to the Factory loading. Our professional loading workers, accompanied with our forklift workers arrange the loading in good order even on the condition that daily loading capacity is overloaded.

Ⅲ. Our professional data management is a guarantee of the real-time update and the unification to all the electrical packing list, invoice.

| Density | 1.24 g/cm3 |

| Melt Flow Index(g/10min) | 3.5(190℃/2.16kg) |

| Heat Distortion Temp | 53℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 11.8% |

| Flexural Strength | 90 MPa |

| Flexural Modulus | 1915 MPa |

| IZOD Impact Strength | 5.4kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

|

Extruder Temperature(℃) |

190 – 220℃ Recommended 215℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

40 – 100mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |