Since the 20th century, the human race has been fascinated with exploring space and understanding what lies beyond Earth. Major organizations such as NASA and ESA have been at the forefront of space exploration, and another important player in this conquest is 3D printing. With the ability to rapidly produce complex parts at low cost, this design technology is becoming increasingly popular in companies. It makes the creation of many applications possible, such as satellites, spacesuits, and rocket components. In fact, according to SmarTech, the market value of private space industry additive manufacturing is expected to reach €2.1 billion by 2026. This raises the question: How can 3D printing help humans excel in space?

Initially, 3D printing was mainly used for rapid prototyping in the medical, automotive, and aerospace industries. However, as the technology has become more widespread, it is being used increasingly for final-purpose components. Metal additive manufacturing technology, particularly L-PBF, has allowed the production of a variety of metals with characteristics and durability suitable for extreme space conditions. Other 3D printing technologies, such as DED, binder jetting, and extrusion process, are also used in the manufacture of aerospace components. In recent years, new business models have emerged, with companies such as Made in Space and Relativity Space using 3D printing technology to design aerospace components.

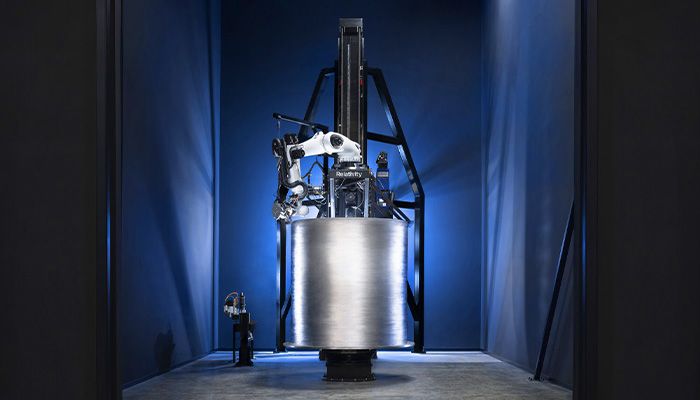

Relativity Space developing 3D printer for aerospace industry

3D printing technology in aerospace

Now that we have introduced them, let's take a closer look at the various 3D printing technologies used in the aerospace industry. First, it should be noted that metal additive manufacturing, especially L-PBF, is the most widely used in this field. This process involves using laser energy to fuse metal powder layer by layer. It is especially suitable for producing small, complex, precise, and customized parts. Aerospace manufacturers can also benefit from DED, which involves depositing metal wire or powder and is mainly used for repairing, coating, or producing customized metal or ceramic parts.

In contrast, binder jetting, although advantageous in terms of production speed and low cost, is not suitable for producing high-performance mechanical parts because it requires post-processing strengthening steps that increase the manufacturing time of the final product. Extrusion technology is also effective in the space environment. It should be noted that not all polymers are suitable for use in space, but high-performance plastics such as PEEK can replace some metal parts due to their strength. However, this 3D printing process is still not very widespread, but it can become a valuable asset for space exploration by using new materials.

Laser Powder Bed Fusion (L-PBF) is a widely used technology in 3D printing for aerospace.

Potential of Space Materials

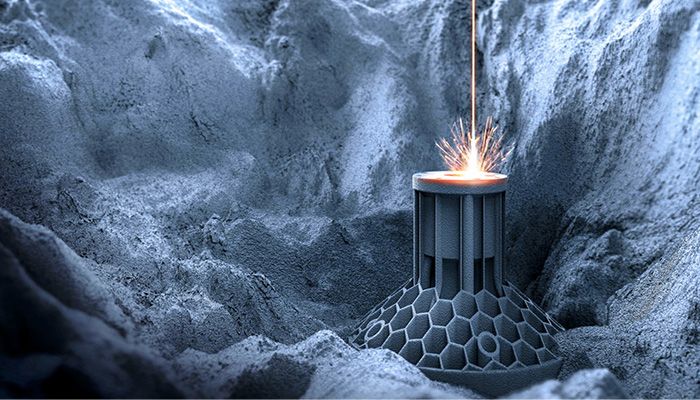

The aerospace industry has been exploring new materials through 3D printing, proposing innovative alternatives that may disrupt the market. While metals such as titanium, aluminum, and nickel-chromium alloys have always been the main focus, a new material may soon steal the spotlight: lunar regolith. Lunar regolith is a layer of dust covering the moon, and ESA has demonstrated the benefits of combining it with 3D printing. Advenit Makaya, a senior manufacturing engineer of ESA, describes lunar regolith as similar to concrete, primarily made up of silicon and other chemical elements such as iron, magnesium, aluminum, and oxygen. ESA has partnered with Lithoz to produce small functional parts such as screws and gears using simulated lunar regolith with properties similar to real moon dust.

Most of the processes involved in manufacturing lunar regolith utilize heat, making it compatible with technologies such as SLS and powder bonding printing solutions. ESA is also using D-Shape technology with the goal of producing solid parts by mixing magnesium chloride with materials and combining it with magnesium oxide found in the simulated specimen. One of the significant advantages of this moon material is its finer print resolution, enabling it to produce parts with the highest precision. This feature could become the primary asset in expanding the range of applications and manufacturing components for future lunar bases.

Lunar Regolith is Everywhere

There is also Martian regolith, referring to subsurface material found on Mars. Currently, international space agencies cannot recover this material, but this has not stopped scientists from researching its potential in certain aerospace projects. Researchers are using simulated specimens of this material and are combining it with titanium alloy to produce tools or rocket components. Initial results indicate that this material will provide higher strength and protect equipment from rusting and radiation damage. Although these two materials have similar properties, lunar regolith is still the most tested material. Another advantage is that these materials can be manufactured on-site without the need to transport raw materials from Earth. In addition, regolith is an inexhaustible material source, helping to prevent scarcity.

The applications of 3D printing technology in the aerospace industry

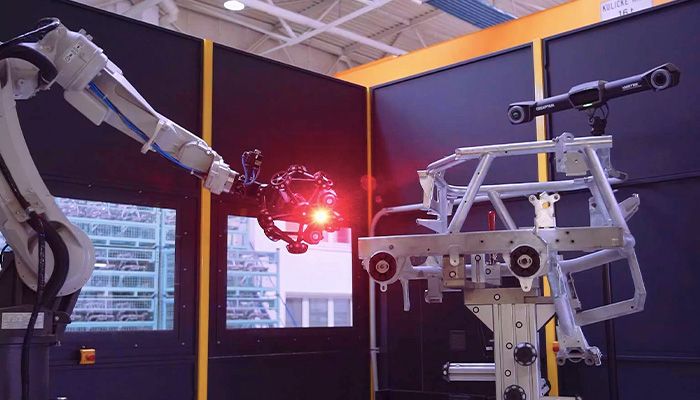

The applications of 3D printing technology in the aerospace industry can vary depending on the specific process used. For example, laser powder bed fusion (L-PBF) can be used to manufacture intricate short-term parts, such as tool systems or space spare parts. Launcher, a California-based startup, used Velo3D's sapphire-metal 3D printing technology to enhance its E-2 liquid rocket engine. The manufacturer's process was used to create the induction turbine, which plays a crucial role in accelerating and driving LOX (liquid oxygen) into the combustion chamber. The turbine and sensor were each printed using 3D printing technology and then assembled. This innovative component provides the rocket with greater fluid flow and greater thrust, making it an essential part of the engine

Velo3D contributed to the use of PBF technology in manufacturing the E-2 liquid rocket engine.

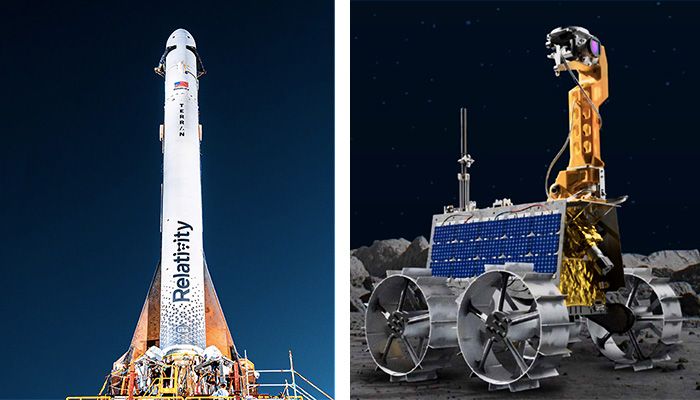

Additive manufacturing has broad applications, including the production of small and large structures. For example, 3D printing technologies such as Relativity Space's Stargate solution can be used to manufacture large parts such as rocket fuel tanks and propeller blades. Relativity Space has proven this through the successful production of the Terran 1, an almost entirely 3D-printed rocket, including a several-meter-long fuel tank. Its first launch on March 23, 2023, demonstrated the efficiency and reliability of additive manufacturing processes.

Extrusion-based 3D printing technology also allows for the production of parts using high-performance materials such as PEEK. Components made of this thermoplastic have already been tested in space and were placed on the Rashid rover as part of the UAE lunar mission. The purpose of this test was to evaluate PEEK's resistance to extreme lunar conditions. If successful, PEEK may be able to replace metal parts in situations where metal parts break or materials are scarce. Additionally, PEEK's lightweight properties may be of value in space exploration.

3D printing technology can be used to manufacture a variety of parts for the aerospace industry.

Advantages of 3D printing in the aerospace industry

Advantages of 3D printing in the aerospace industry include improved final appearance of parts compared to traditional construction techniques. Johannes Homa, CEO of Austrian 3D printer manufacturer Lithoz, stated that "this technology makes parts lighter." Due to design freedom, 3D printed products are more efficient and require fewer resources. This has a positive impact on the environmental impact of part production. Relativity Space has demonstrated that additive manufacturing can significantly reduce the number of components required to manufacture spacecraft. For the Terran 1 rocket, 100 parts were saved. In addition, this technology has significant advantages in production speed, with the rocket being completed in less than 60 days. In contrast, manufacturing a rocket using traditional methods could take several years.

Regarding resource management, 3D printing can save materials and, in some cases, even allow for waste recycling. Finally, additive manufacturing may become a valuable asset for reducing the take-off weight of rockets. The goal is to maximize the use of local materials, such as regolith, and minimize the transport of materials within spacecraft. This makes it possible to carry only a 3D printer, which can create everything on-site after the trip.

Made in Space has already sent one of their 3D printers to space for testing.

Limitations of 3D printing in space

Although 3D printing has many advantages, the technology is still relatively new and has limitations. Advenit Makaya stated, "One of the main problems with additive manufacturing in the aerospace industry is process control and validation." Manufacturers can enter the lab and test each part's strength, reliability, and microstructure before validation, a process known as non-destructive testing (NDT). However, this can be both time-consuming and expensive, so the ultimate goal is to reduce the need for these tests. NASA recently established a center to address this issue, focused on the rapid certification of metal components manufactured by additive manufacturing. The center aims to use digital twins to improve computer models of products, which will help engineers better understand the performance and limitations of parts, including how much pressure they can withstand before fracture. By doing so, the center hopes to help promote the application of 3D printing in the aerospace industry, making it more effective in competing with traditional manufacturing techniques.

These components have undergone comprehensive reliability and strength testing.

On the other hand, the verification process is different if manufacturing is done in space. ESA's Advenit Makaya explains, "There is a technique that involves analyzing the parts during printing." This method helps determine which printed products are suitable and which are not. Additionally, there is a self-correction system for 3D printers intended for space and is being tested on metal machines. This system can identify potential errors in the manufacturing process and automatically modify its parameters to correct any defects in the part. These two systems are expected to improve the reliability of printed products in space.

To validate 3D printing solutions, NASA and ESA have established standards. These standards include a series of tests to determine the reliability of parts. They consider powder bed fusion technology and are updating them for other processes. However, many major players in the materials industry, such as Arkema, BASF, Dupont, and Sabic, also provide this traceability.

Living in space?

With the advancement of 3D printing technology, we have seen many successful projects on Earth that use this technology to build houses. This makes us wonder whether this process might be used in the near or distant future to construct inhabitable structures in space. While living in space is currently unrealistic, building houses, particularly on the moon, can be beneficial for astronauts in executing space missions. The goal of the European Space Agency (ESA) is to build domes on the moon using lunar regolith, which can be used to construct walls or bricks to protect astronauts from radiation. According to Advenit Makaya from ESA, lunar regolith is composed of about 60% metal and 40% oxygen and is an essential material for astronaut survival because it can provide an endless source of oxygen if extracted from this material.

NASA has awarded a $57.2 million grant to ICON for developing a 3D printing system for building structures on the lunar surface and is also collaborating with the company to create a Mars Dune Alpha habitat. The goal is to test living conditions on Mars by having volunteers live in a habitat for one year, simulating conditions on the Red Planet. These efforts represent critical steps towards directly constructing 3D printed structures on the moon and Mars, which could eventually pave the way for human space colonization.

In the distant future, these houses could enable life to survive in space.

Post time: Jun-14-2023