Orange TPU Filament 3D printing materials

Product Features

| Brand | Torwell |

| Material | Premium grade Thermoplastic Polyurethane |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.05mm |

| Length | 1.75mm(1kg) = 330m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 65˚C for 8h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

More Colors

Color Available

| Basic color | White, Black, Red, Blue, Yellow, Green, Grey, Orange, Transparent |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll TPU filament 1.75mm with desiccant in vacuums package.

Each spool in individual box (Torwell box, Neutral box, or Customized box available).

8boxes per carton (carton size 44x44x19cm).

Care Instructions

Please store 3D printer filament in a cool dry place. TPU filament, if exposed to moisture, will bubble and spurt from the extruding nozzle. TPU filament can be dried from a food dehydrator, oven, or from any source of hot air.

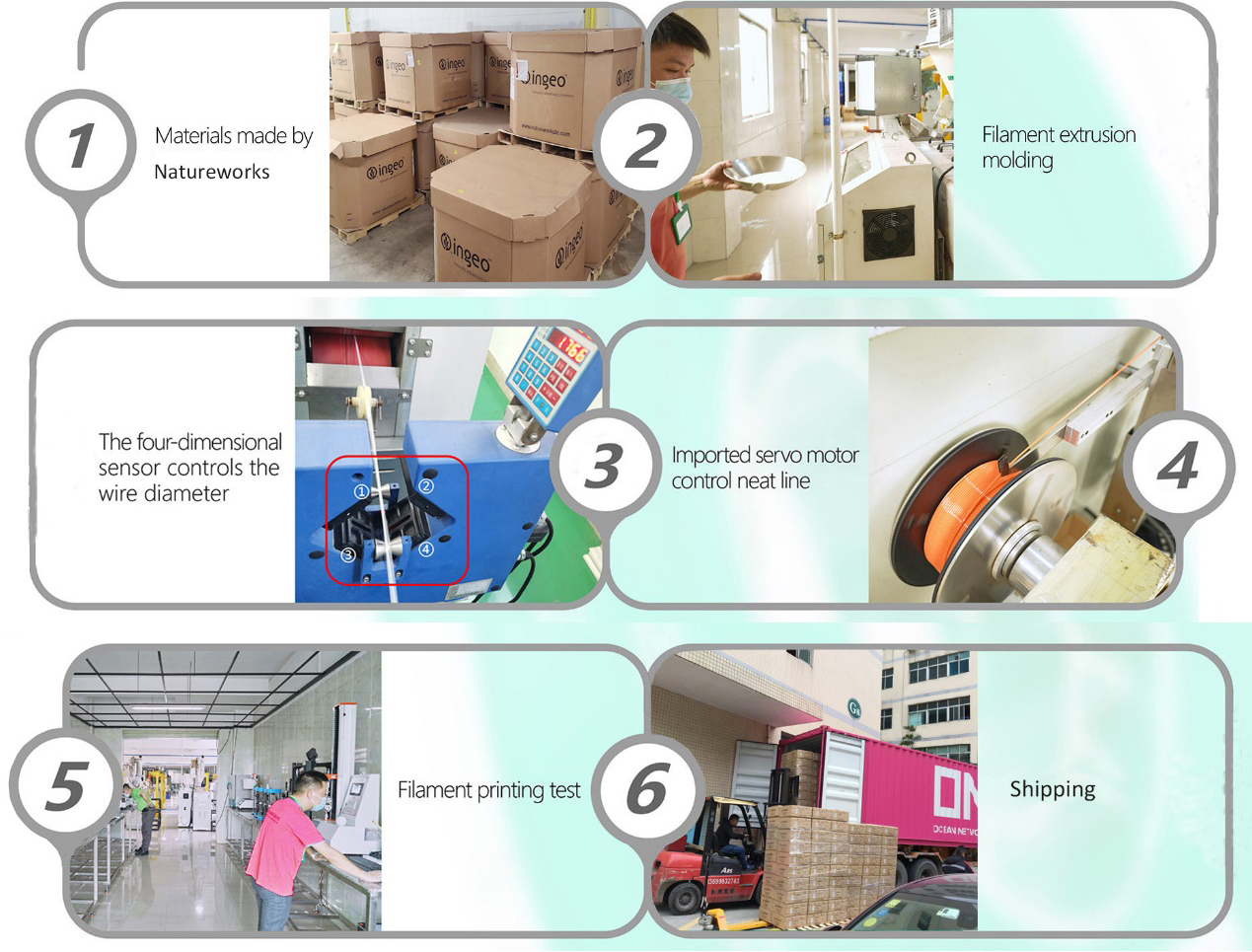

Factory Facility

Why Choose Torwell TPU?

Torwell TPU gains popularity among 3D Printing community for its balance of rigidity and flexibility.

In addition, with a 95A Shore Hardness and improved bed adhesion, it is easier to print even with a stock elementary 3D Printer like the Creality Ender 3.

Torwell TPU will not disappoint if you are looking for flexible filament. From drone parts, phone cases, to small toys, all can be printed with ease.

FAQ

A: Our product scope including PLA, PLA+, ABS, HIPS, Nylon, TPE Flexible, PETG, PVA, Wood, TPU, Metal, Biosilk, Carbon Fiber, ASA filament etc.

A: Yes, products can be customized according to your requirements. MOQ will be different depending on products available or not.

A: 30% T/T deposit before production, 70% T/T balance before shipment.

A: Yes, TPU 3D printer filament is known for its flexibility, which is Shore A 95.

A: TPU printing temperature varies between 225 to 245 DegC, and print bed temperature for TPU is relatively low as 45 to 60 Deg C as compared to ABS.

A: Usually, a cooling fan is not needed for TPU while printing at normal speed and temperature. But when the Nozzle temperature is high (250 DegC) and print speed is 40 mm/s, then a fan could be beneficial. Fans can be used while printing bridges using TPU.

High Durability

Torwell TPU flexible filament is a material that is soft and elastic like rubber, similar to the Flexible TPE but typing easier and harder than TPE. It allows for repeated movement or impact without cracking.

High Flexibility

Flexible materials have a property called Shore hardness, which determines the flexibility or hardness of a material. Torwell TPU has a Shore-A hardness of 95 and can stretch 3 times more than its original length.

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 1.5(190℃/2.16kg) |

| Shore Hardness | 95A |

| Tensile Strength | 32 MPa |

| Elongation at Break | 800% |

| Flexural Strength | / |

| Flexural Modulus | / |

| IZOD Impact Strength | / |

| Durability | 9/10 |

| Printability | 6/10 |

|

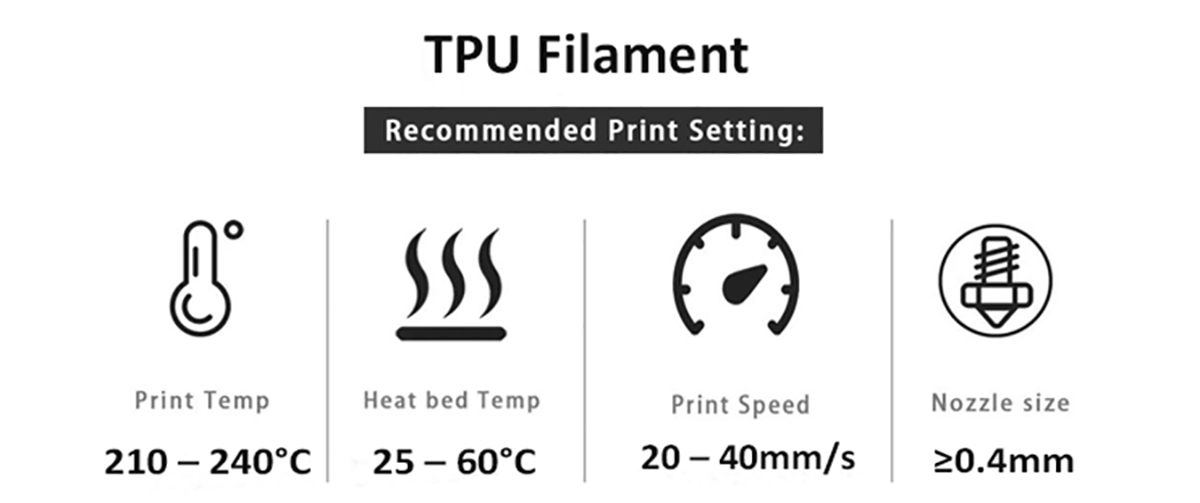

Extruder Temperature(℃) |

210 – 240℃ Recommended 235℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

20 – 40mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |