PETG Carbon Fiber 3D Printer Filament, 1.75mm 800g/spool

Product Features

| Brand | Torwell |

| Material | 20% High-Modulus Carbon Fibers composited with 80% PETG |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 800g/spool; 250g/spool; 500g/spool; 1kg/spool; |

| Gross weight | 1.0Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(800g) = 260m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 60˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn

sealed plastic bag with desiccants |

More Colors

Drawing Show

Package

| Density | 1.3 g/cm3 |

| Melt Flow Index(g/10min) | 5.5(190℃/2.16kg) |

| Heat Distortion Temp | 85℃, 0.45MPa |

| Tensile Strength | 52.5 MPa |

| Elongation at Break | 5% |

| Flexural Strength | 45 MPa |

| Flexural Modulus | 1250 MPa |

| IZOD Impact Strength | 8kJ/㎡ |

| Durability | 6/10 |

| Printability | 9/10 |

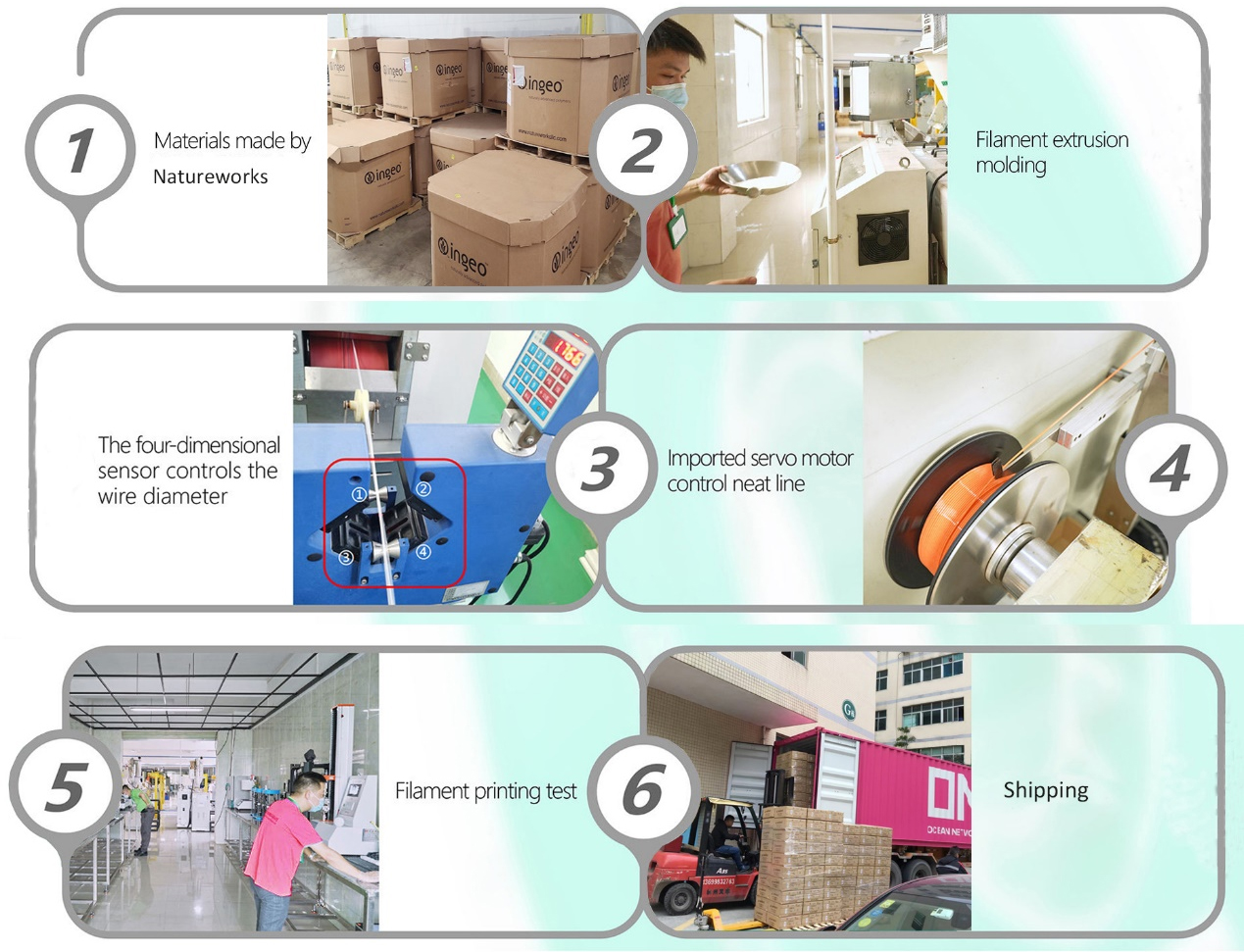

Factory Facility

Torwell, an excellent manufacturer with more than 10years experiences on 3D printing filament.

Why PETG Carbon Fiber filament?

Carbon Fiber PETG 3D printing filament has a very high strength to weight ratio, high stiffness and rigidity, resistance to abrasion and wear and tear, good chemical resistance to dilute aqueous solutions of mineral acids, bases, salts, and soaps, as well as aliphatic hydrocarbons, alcohols, and a wide range of oils.

What Is It?

Fibers 5-10 micrometers wide made of carbon. The fibers are aligned following the axis of the material. This, along with their physical makeup, are what give this material its excellent properties.

What Does It Do?

Carbon Fibers demonstrate a lot of desirable material properties:

• high stiffness

• high tensile strength

• high heat tolerance

• high chemical resistance

• low weight

low thermal expansion

How Does It Work?

Reinforcing plastic with carbon fibers produces a 3D printing filament which exhibits the best properties of both the carbon fibers and the plastic of choice.

What Is It Good For?

Ideal for any applications which require light weight and rigidity. For these reasons, carbon fiber reinforced filament is very popular in aerospace, civil engineering, the military, and motorsports.

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently and the printer will experience extrusion issues.

Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

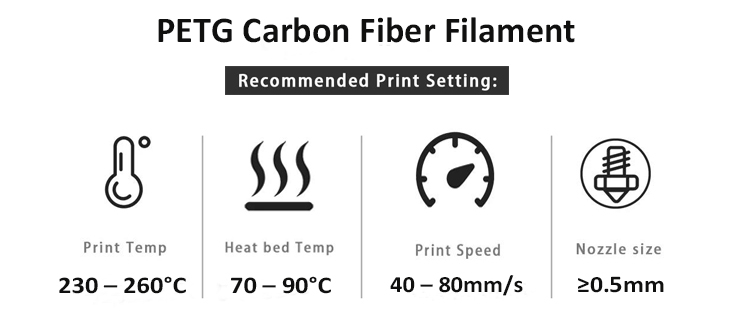

| Extruder Temperature(℃) | 230 – 260℃Recommended 245℃ |

| Bed temperature(℃) | 70 – 90°C |

| Nozzle Size | ≥0.5mm It’s better to use Hardened Steel Nozzles. |

| Fan Speed | On 100% |

| Printing Speed | 40 – 80mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |