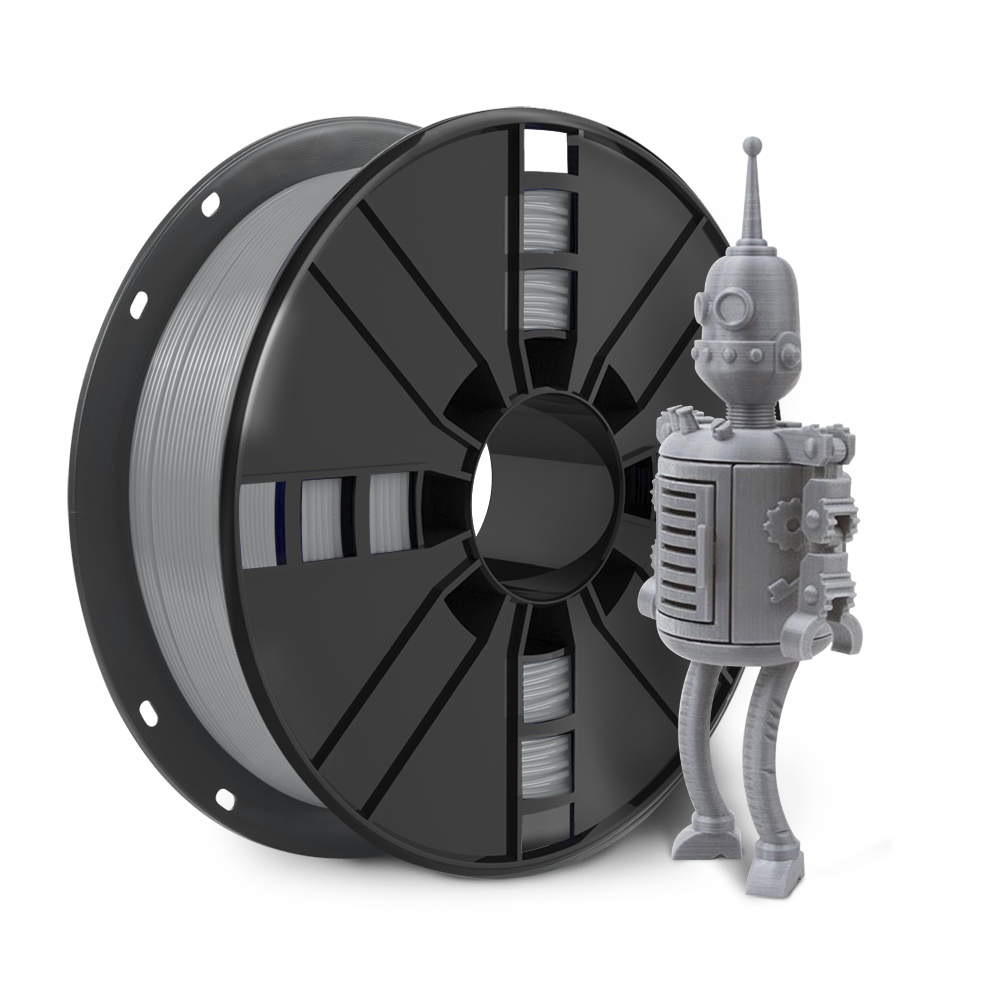

PLA Filament Grey color 1kg spool

| Brand | Torwell |

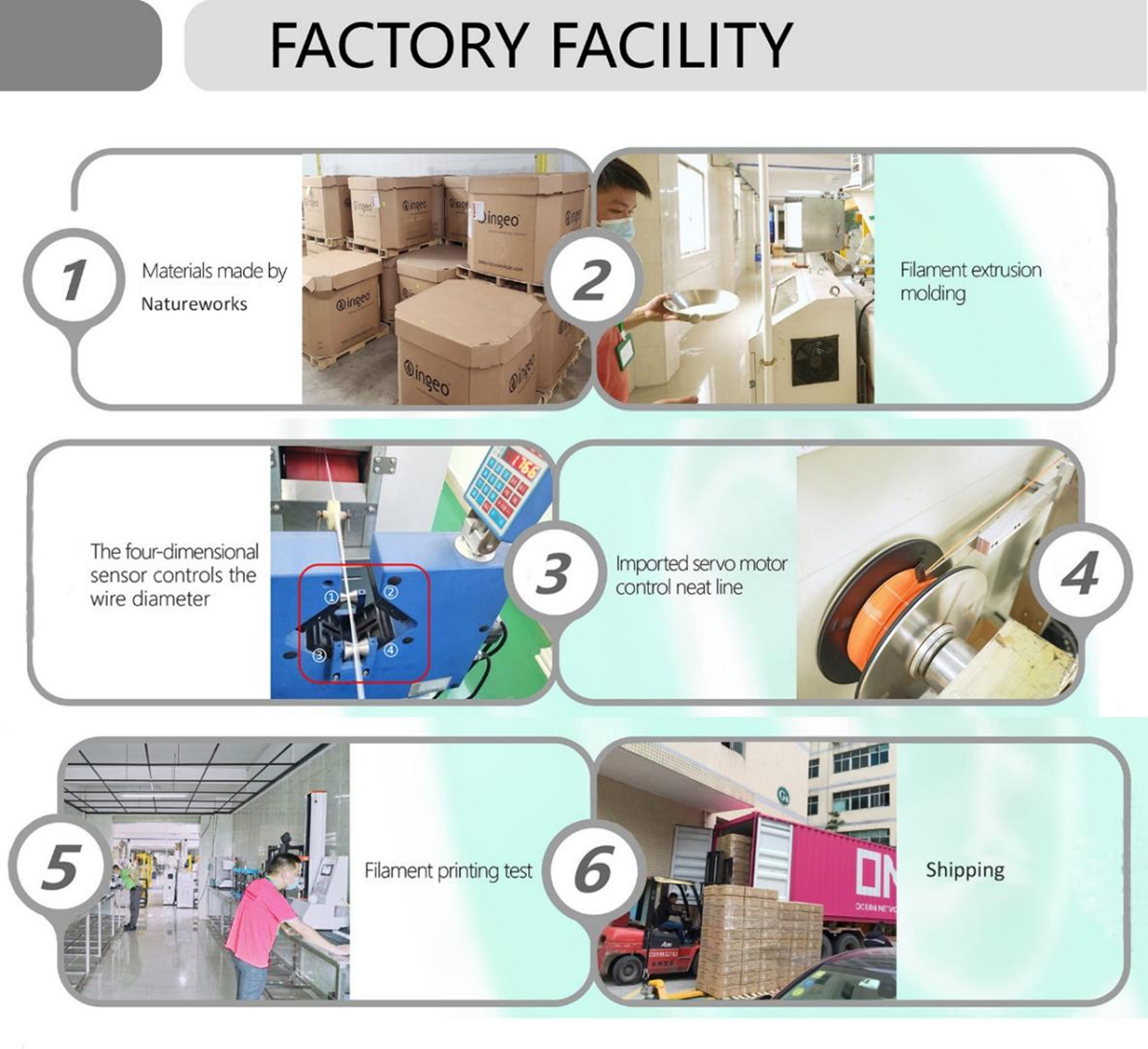

| Material | Standard PLA (NatureWorks 4032D / Total-Corbion LX575) |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.02mm |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

Color for Choose:

Color Available

Normal series: White, Black, Red, Blue, Yellow, Green, Nature, Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent

Florescent series: luorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue

Luminous series: Luminous grene, Luminous blue

Color changing series: Blue green to yellow green, Blue to white, Purple to Pink, Grey to White

Customized color availble. You just the let us know RAL or Pantone code.

Print Model Show

Package Details

1kg roll PLA Filament with desiccant in vaccum package.

Each spool in individual box (Torwell box, Neutral box, or Customized box avilable).

8boxes per carton (carton size 44x44x19cm).

Torwell has over 10 years 3D filament R&D experiences, and produce all kinds of filaments, including PLA, PLA+, PETG, ABS, TPU, Wood PLA, Silk PLA, Marble PLA, ASA, Carbon Fiber, Nylon, PVA, Metal, Cleaning filament etc. 3D filament in large scale with premium quality, which contribute to product cost-effective and reliable for all common 1.75mm FDM 3D printers.

Tips for PLA filament Printing

To help you with 3D printing PLA filament, we’re giving our 5 tips for using some tips for your to print with PLA filament:

1. Temperature

When printing with PLA filament, you are advise to begin with a starting temperature of 195 °C, it will ensure that you give yourself the best chance of success. The temperature can then be reduced or increased by 5-degree increments to obtain the right quality of print and strength so that they complement each other. To improve the adhesion to the build plate, it is better to heated the print bed to 60 degrees.

2. Temperature too high

If the temperature is too high then strings will appea. The extruder will leak PLA material when it moves between the different areas during printing. Should this occur, then you will be required to decrease the temperature. Do this in increments of 5 degrees per step, until the extruder stops leaking so much material.

3. Temperature too low

If the the printing temperature too cold, you will find that the filament will fail to adhere to the previous layer. It will create a surface which looks and feels rough. Meanwhile, the part will be weaker and can then be pulled apart easily. If this should happen, the print head temperature should be increased by 5 degree increments until the printing looks good and the line segments for each layer are right. As a result the part will be stronger once the job has completed.

4. Keep the PLA filament dry

PLA material needs to be storaged in a cool and dark place, preferably in a sealed bag, which can hep you to preserve the quality of the PLA plastics. It will ensure that the result of the printing process is as expected.

| Density | 1.24 g/cm3 |

| Melt Flow Index(g/10min) | 3.5(190℃/2.16kg) |

| Heat Distortion Temp | 53℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 11.8% |

| Flexural Strength | 90 MPa |

| Flexural Modulus | 1915 MPa |

| IZOD Impact Strength | 5.4kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

|

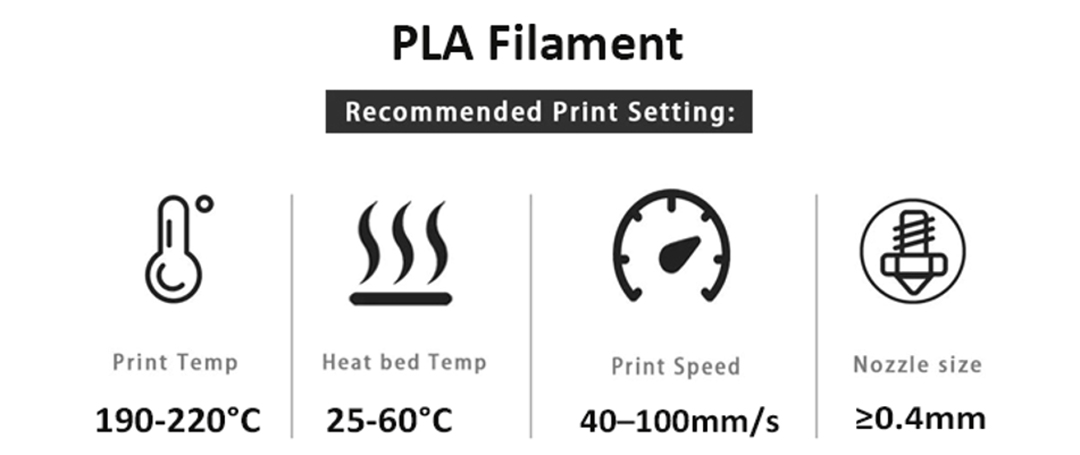

Extruder Temperature(℃) |

190 – 220℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

40 – 100mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |