PLA Silk 3D filament blue 1.75mm

Product Features

Torwell SILK 3D PLA printer filaments are developed especially for our daily printing. With features of silky shining texture and very easy to print, whenever we are printing home decorations, toys & games, households, fashions, prototypes, Torwell SILK 3D PLA filament is always your Excellent Choice.

| Brand | Torwell |

| Material | polymer composites Pearlescent PLA (NatureWorks 4032D) |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 325m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

[Upgrade Silk PLA Filament]

Because of the latest patented material, Silk PLA Blue filament is more smooth and shiny than ever. What you 3d printing out will be as glossy as in the pictures, no exaggeration. We specialize in silk PLA filament and bring the best 3D printing creative experience.

[Tangle-Free and Easy to Print]

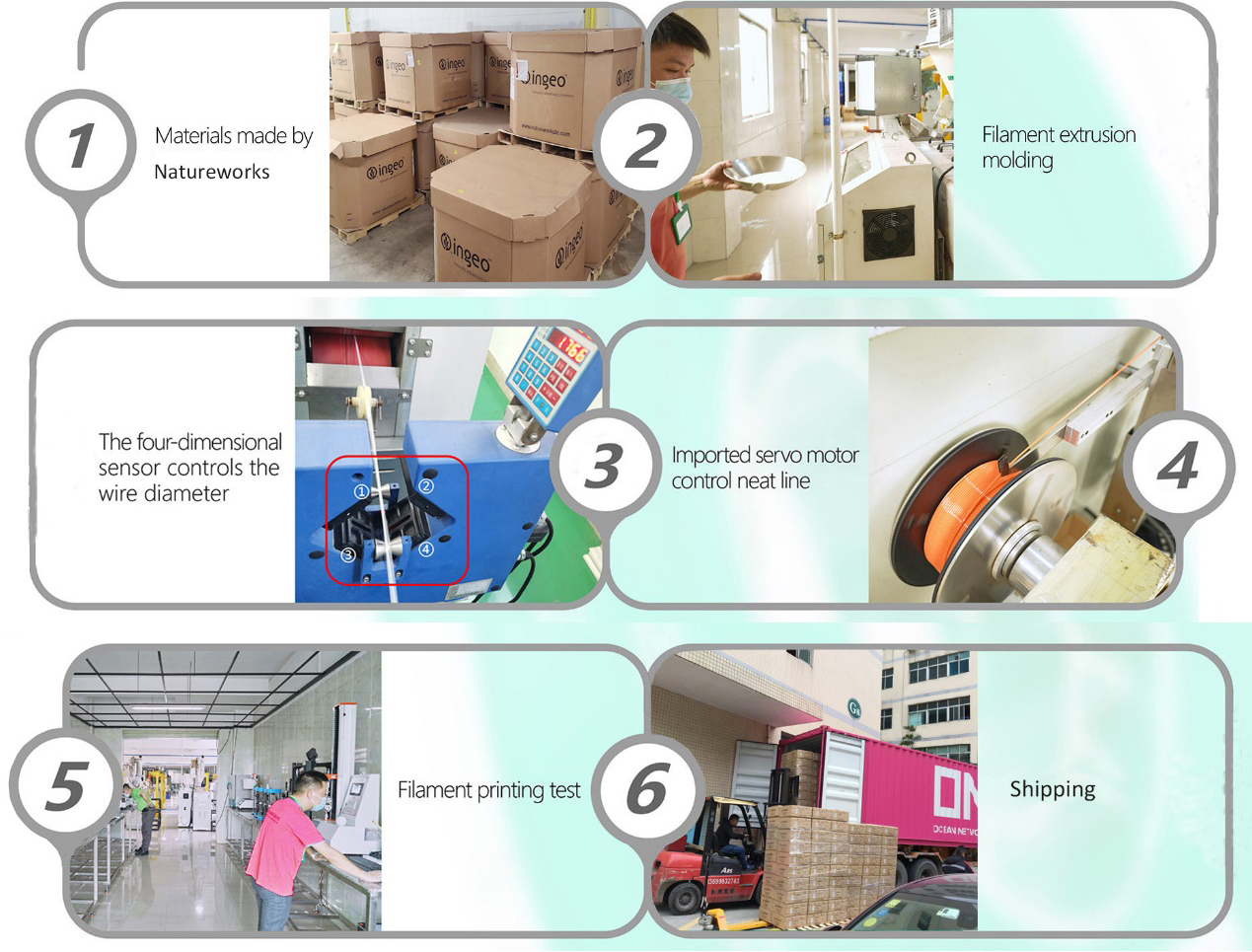

Excellent Production Line Controlled, To Reduce Warpage and Shrinkage, To Make Sure Printing with No-Bubble and No-Jam, It’s Well Wrapped and Tangle-Free, It’s Easy to Print and Smooth Extrusion with Stable Printing Performance.

[Dimensional Accuracy & Consistency]

Advanced CCD diameter measuring and self-adaptive control system in the manufacturing guarantee these PLA filaments of 1.75 mm diameter, Accuracy +/- 0.03 mm which will give you smoother 3D printing.

[Cost-effective and Wide Compatibility]

With over 11 years’ 3D filaments R & D experience, Torwell is capable of manufacturing all kinds of filaments in large scale with premium quality, which contribute to Torwell filament cost-effective and reliable for most common 3D printers, such as MK3, Ender 3, Monoprice FlashForge and more

More Colors

Color Available

| Basic color | White, Black, Red, Blue, Yellow, Green, Silver, Grey, Gold, Orange, Pink |

|

Accept Customer PMS Color |

|

Model Show

Package

Each Spool Filament is Packed in a Sealed Vacuum Bag, To Keep it Dry and Maintain Its High Performance for Long Time

1kg roll PLA Silk 3D filament with desiccant in vacuums package

Each spool in individual box (Torwell box, Neutral box, or Customized box available)

8boxes per carton (carton size 44x44x19cm)

Factory Facility

FAQ

A: Make sure that the printing temperature matches well with the printing speed. You need to adjust the printing temperature to 200-220℃.

A: Silk PLA has silk texture, smooth surface and strong toughness, which is not suitable for printing high-precision or small-sized models.

A: Inconstant filament diameter, the lower nozzle temperature and frequent replacement with different kinds of filaments will lead to this problem. So, before you get started, clean the nozzle and turn up the temperature to a proper value.

A: we will vacuum process the materials to place the consumables to be damp, and then put them in the carton box to protection damage during transportation

Offer free sample for testing. Just email us info@torwell3d.com. Or Skype alyssia.zheng.

We will feedback to you within 24 hours.

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 4.7(190℃/2.16kg) |

| Heat Distortion Temp | 52℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 14.5% |

| Flexural Strength | 65 MPa |

| Flexural Modulus | 1520 MPa |

| IZOD Impact Strength | 5.8kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

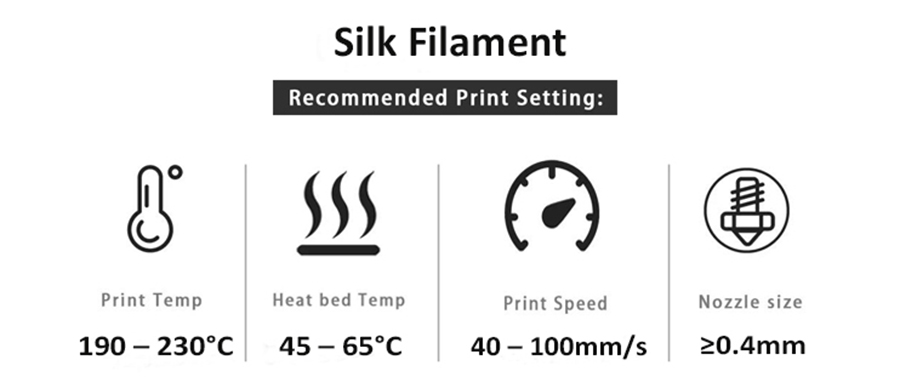

| Extruder Temperature(℃) | 190 – 230℃Recommended 215℃ |

| Bed temperature(℃) | 45 – 65°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | On 100% |

| Printing Speed | 40 – 100mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |

Why can’t the filaments stick to the hotbed easy?

1). Check the temperature setting before printing, SILK PLA filament temperature about 190-230℃;

2). Check if the plate surface has been used for a long time, it is recommended to apply PVA glue;

3). If the first layer has poor adhesion, it is recommended to re-level the print substrate to reduce the distance between the nozzle and the surface plate;