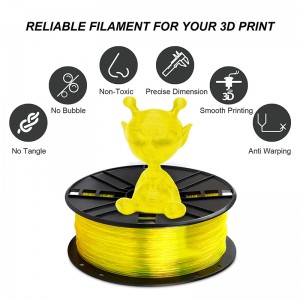

Rubber 1.75mm TPU 3D Printer Filament Yellow color

Product Features

Torwell TPU Flexible Filament is a thermoplastic polyurethane (TPU) based filament specifically engineered to work on most desktop 3D printers. It has a shore hardness of 95A and can stretch 3 times more than its original length. Excellent bed adhesion, low-warp and low-odor, make these flexible 3D filaments easy to print.

| Brand | Torwell |

| Material | Premium grade Thermoplastic Polyurethane |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.05mm |

| Length | 1.75mm(1kg) = 330m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 65˚C for 8h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

More Colors

Color Available

| Basic color | White, Black, Red, Blue, Yellow, Green, Grey, Orange, Transparent |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll TPU filament with desiccant in vacuums package.

Each spool in individual box (Torwell box, Neutral box, or Customized box available).

8boxes per carton (carton size 44x44x19cm).

Printing Tips

1.A consistent and slow feed rate is key to successful printing with TPU.

2. As a hygroscopic material, TPU absorbs moisture easily, drying the filament before printing allows for smooth finish.

3. Printing TPU Filament with a direct drive extruder is recommended, though it is possible to print with a Bowden extruder, it requires more tweaking.

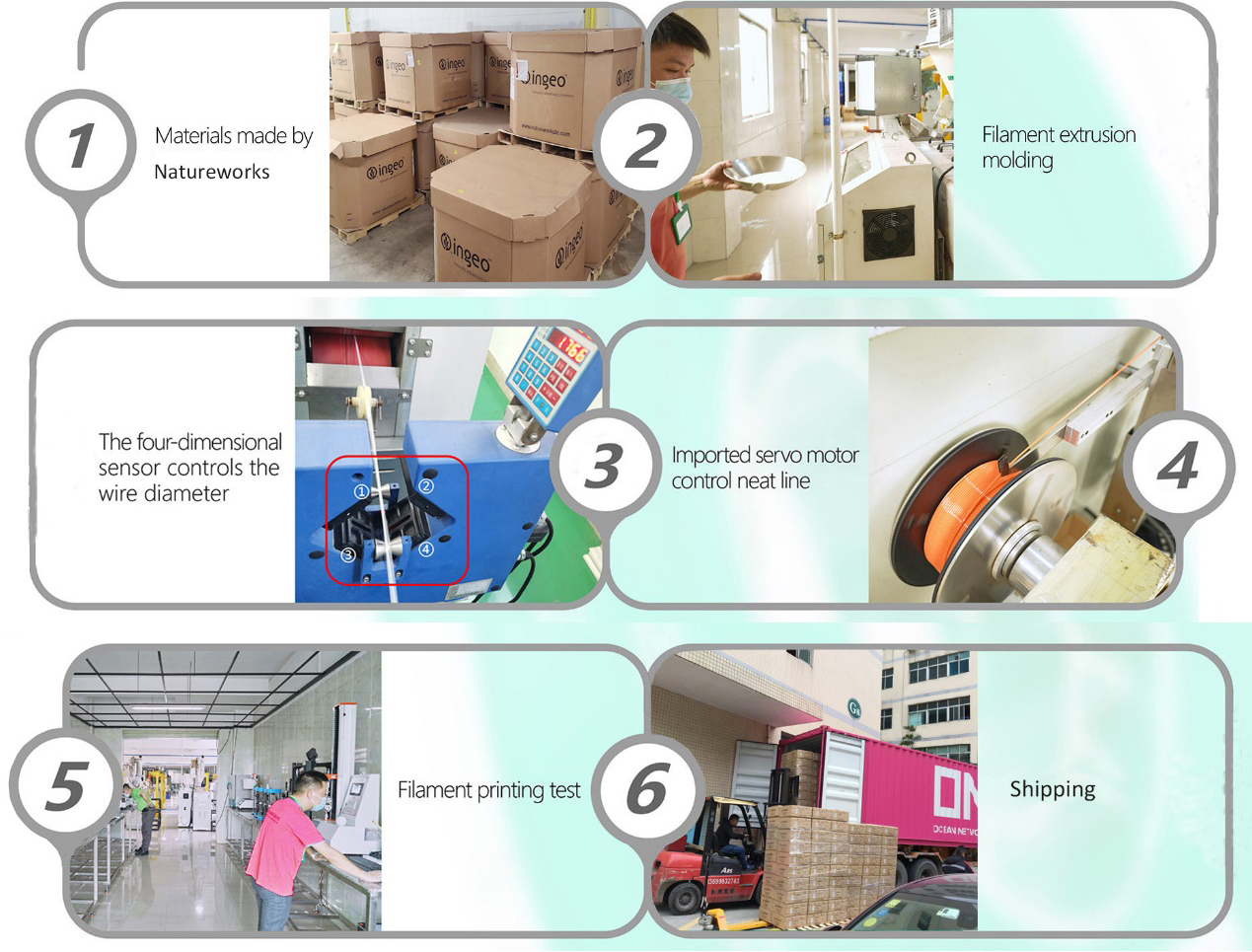

Factory Facility

FAQ

A : We are manufacturer for 3D filament more than 10 years in China.

A: our material will be baked before production to prevent the formation of bubbles .

A: we will vacuum process the materials to place the consumables to be damp, and then put them in the carton box to protection damage during transportation.

A: yes, we do business in every corner of the world , please contact us for detailed delivery charges

Torwell Advantages

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

Offer free sample for testing. Just email us info@torwell3d.com. Or Skype alyssia.zheng.

We will feedback to you within 24 hours.

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 1.5(190℃/2.16kg) |

| Shore Hardness | 95A |

| Tensile Strength | 32 MPa |

| Elongation at Break | 800% |

| Flexural Strength | / |

| Flexural Modulus | / |

| IZOD Impact Strength | / |

| Durability | 9/10 |

| Printability | 6/10 |

Why can’t the filaments stick to the build bed?

1. You need to apply a thin layer of tick glue to the print platform.

2.Check the temperature setting before printing, TPU filaments have lower extrusion temperature.

3.It is recommended to re-level the print substrate to reduce the distance between the nozzle and the surface plate.

4. Check if the plate surface has been used for a longtime.

|

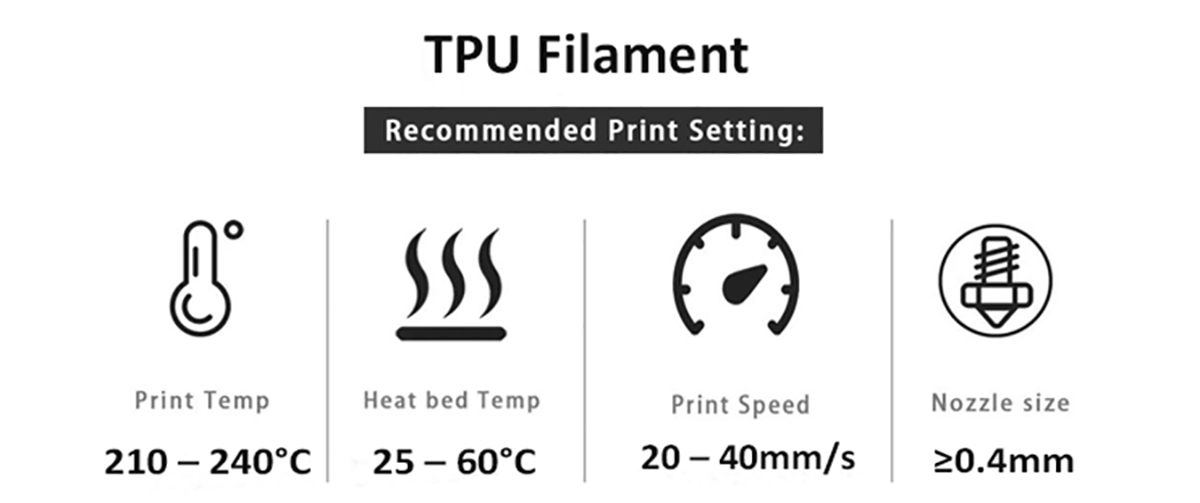

Extruder Temperature(℃) |

210 – 240℃Recommended 235℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

20 – 40mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |