Silk Shiny Fast Color Gradient Change Rainbow Multicolored 3D Printer PLA Filament

Product Features

The unique feature of Torwell rainbow multicolor silk PLA filament is its rainbow color effect. The material is composed of a mixture of PLA and other substances, which creates a gradient effect of multiple colors on the printed object, making it ideal for making art and decorative objects. In addition, Torwell rainbow multicolor silk PLA filament has excellent mechanical properties and a glossy surface, ensuring high quality and long-lasting use of the printed object.

| Brand | Torwell |

| Material | polymer composites Pearlescent PLA (NatureWorks 4032D) |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 325m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker and any other FDM 3D printers |

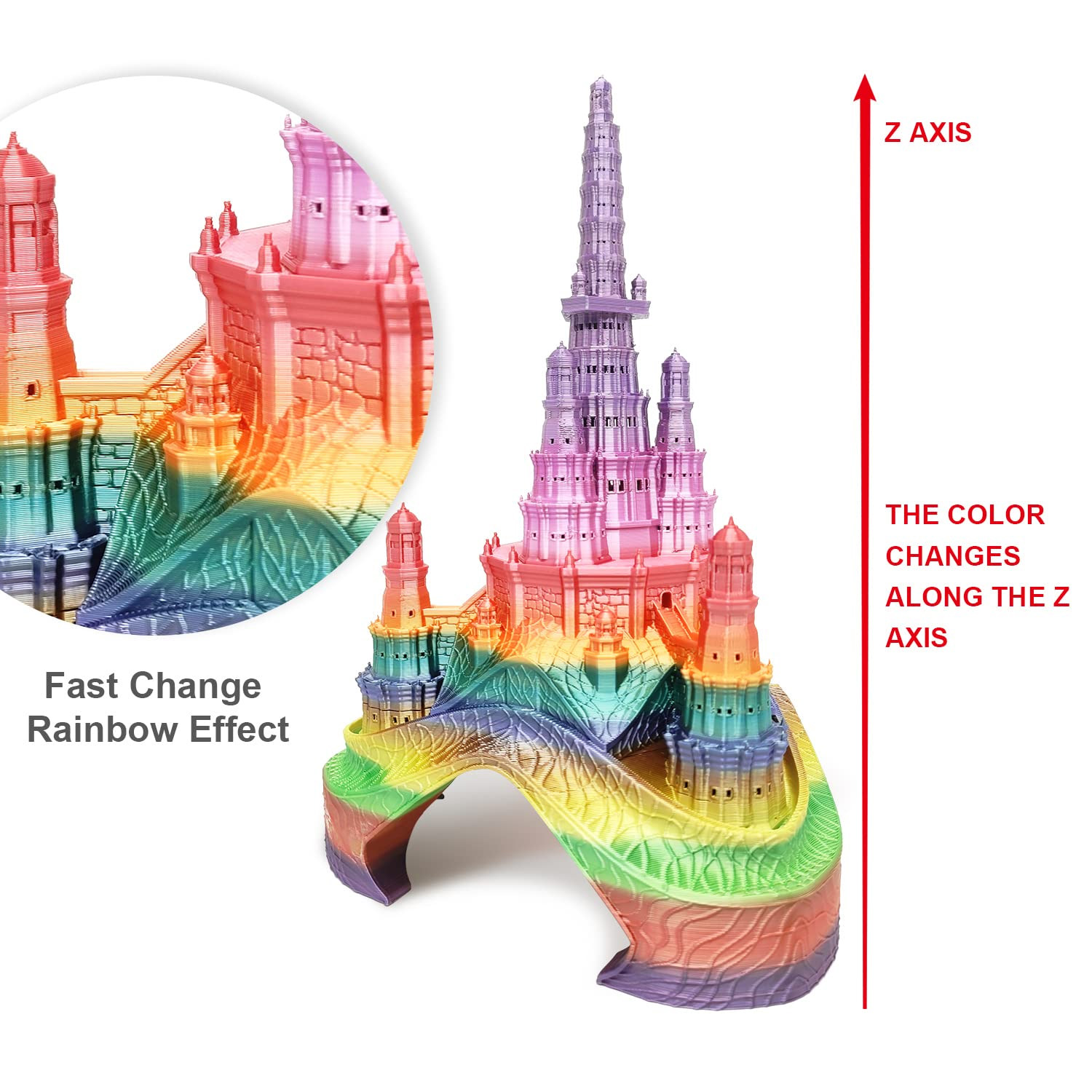

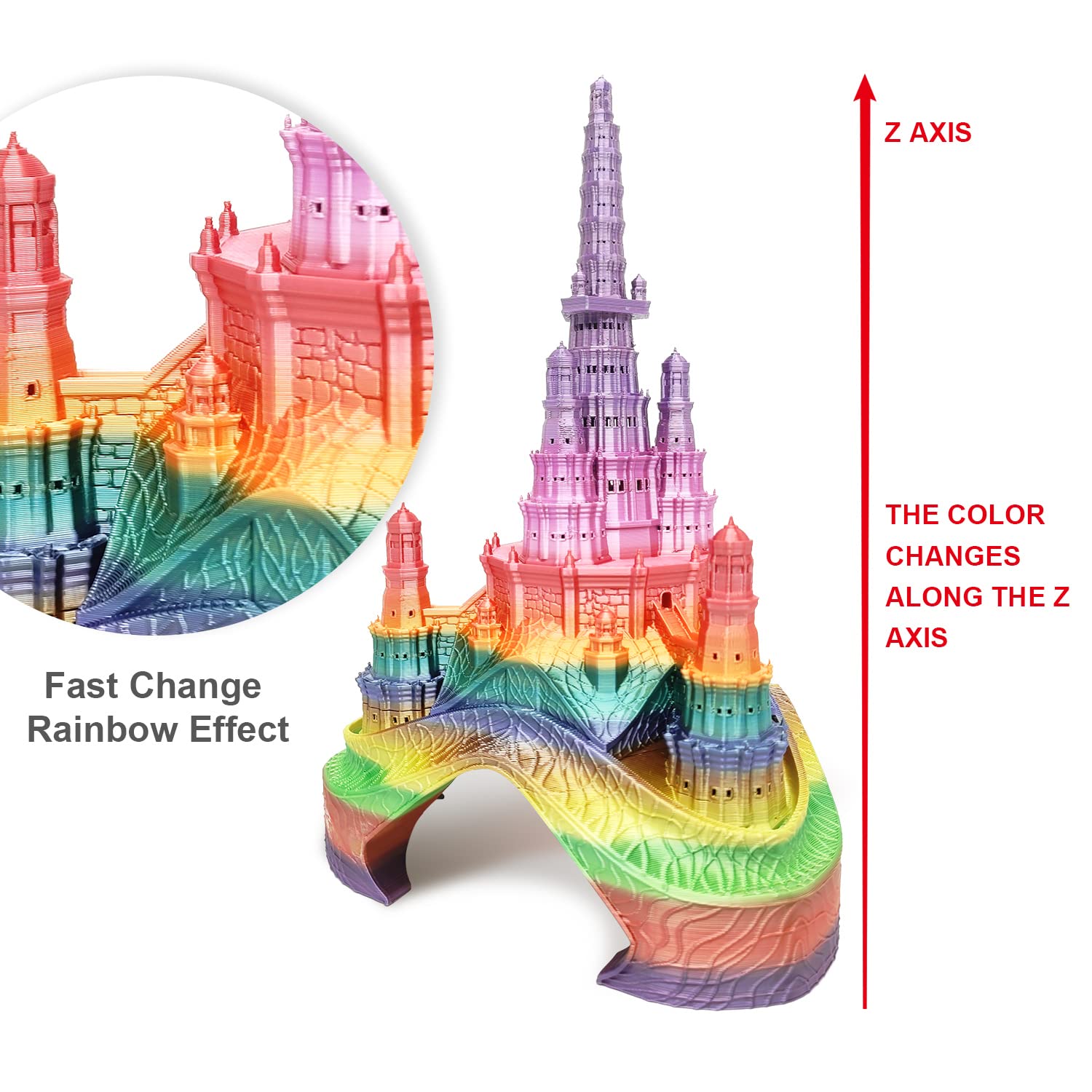

Model Show

The Unique Silk Metallic Rainbow Multi Colors:

It's Gradient Color, Around Each 3 - 5 Meters Change Color, It's Random to Change from One Color to Another; It's Amazing to Print Multi Unique Colors Item in One Spool Filament which support Your Innovation and Design in 3D Printing World Very Well!

Certifications:

ROHS; REACH; SGS; MSDS; TUV

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 4.7(190℃/2.16kg) |

| Heat Distortion Temp | 52℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 14.5% |

| Flexural Strength | 65 MPa |

| Flexural Modulus | 1520 MPa |

| IZOD Impact Strength | 5.8kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

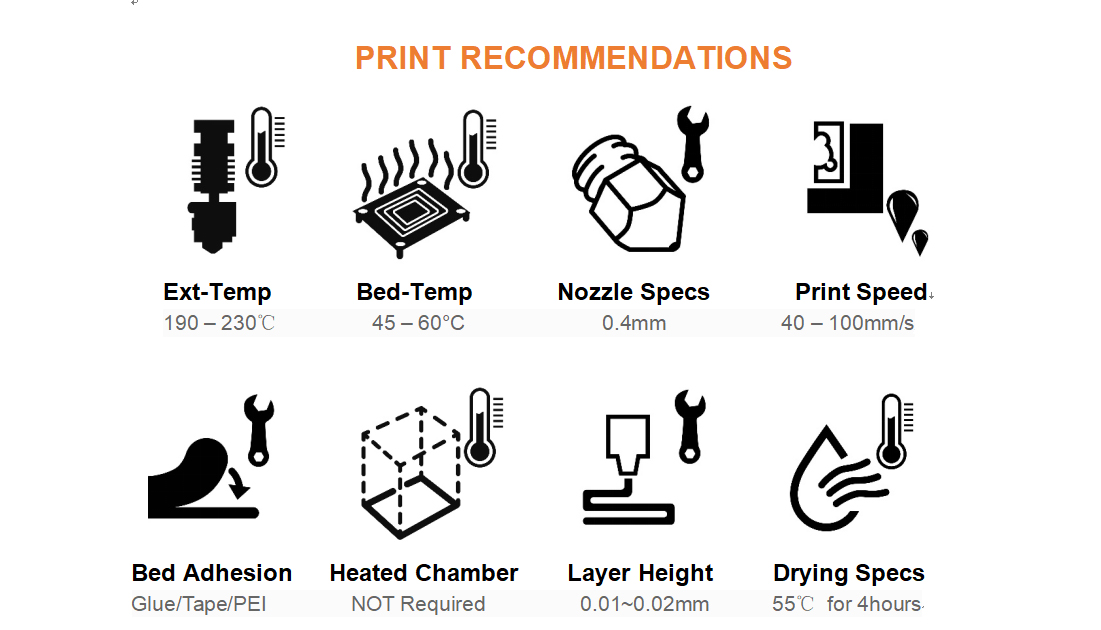

1. In order to achieve the best printing effect with rainbow multicolor silk PLA filament, it is recommended to use a nozzle diameter of 0.4 mm or smaller. Smaller nozzle diameters can achieve better detail and surface quality. The recommended printing temperature is between 200-220°C, with a bed temperature between 45-65°C. The optimal printing speed is around 50-60 mm/s, and the layer height should be between 0.1-0.2 mm.

2. Be sure to fix the filament end after each time use, such as insert the free end of the filament into the hole to avoid the filament being tangled for next time use.

3. In order to extend the life of your filament, please store it in a dry, sealed bag or box.

| Extruder Temperature(℃) | 190 – 230℃Recommended 215℃ |

| Bed temperature(℃) | 45 – 65°C |

| Nozzle Size | 0.4mm |

| Fan Speed | On 100% |

| Printing Speed | 40 – 100mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |

Printing Tips:

1) In order to achieve the best printing effect with rainbow multicolor silk PLA filament, it is recommended to use a nozzle diameter of 0.4 mm or smaller. Smaller nozzle diameters can achieve better detail and surface quality. The recommended printing temperature is between 200-220°C, with a bed temperature between 45-65°C. The optimal printing speed is around 50-60 mm/s, and the layer height should be between 0.1-0.2 mm.

2) Be sure to fix the filament end after each time use, such as insert the free end of the filament into the hole to avoid the filament being tangled for next time use.

3) In order to extend the life of your filament, please store it in a dry, sealed bag or box.