Silky Shiny PLA filament Yellow Color

Product Features

| Brand | Torwell |

| Material | polymer composites Pearlescent PLA (NatureWorks 4032D) |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 325m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctnsealed plastic bag with desiccants |

More Colors

Color Available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Silver, Grey, Gold, Orange, Pink |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll silk PLA 3D printer Filament with desiccant in vaccum package Each spool in individual box (Torwell box, Neutral box, or Customized box avilable) 8boxes per carton (carton size 44x44x19cm)

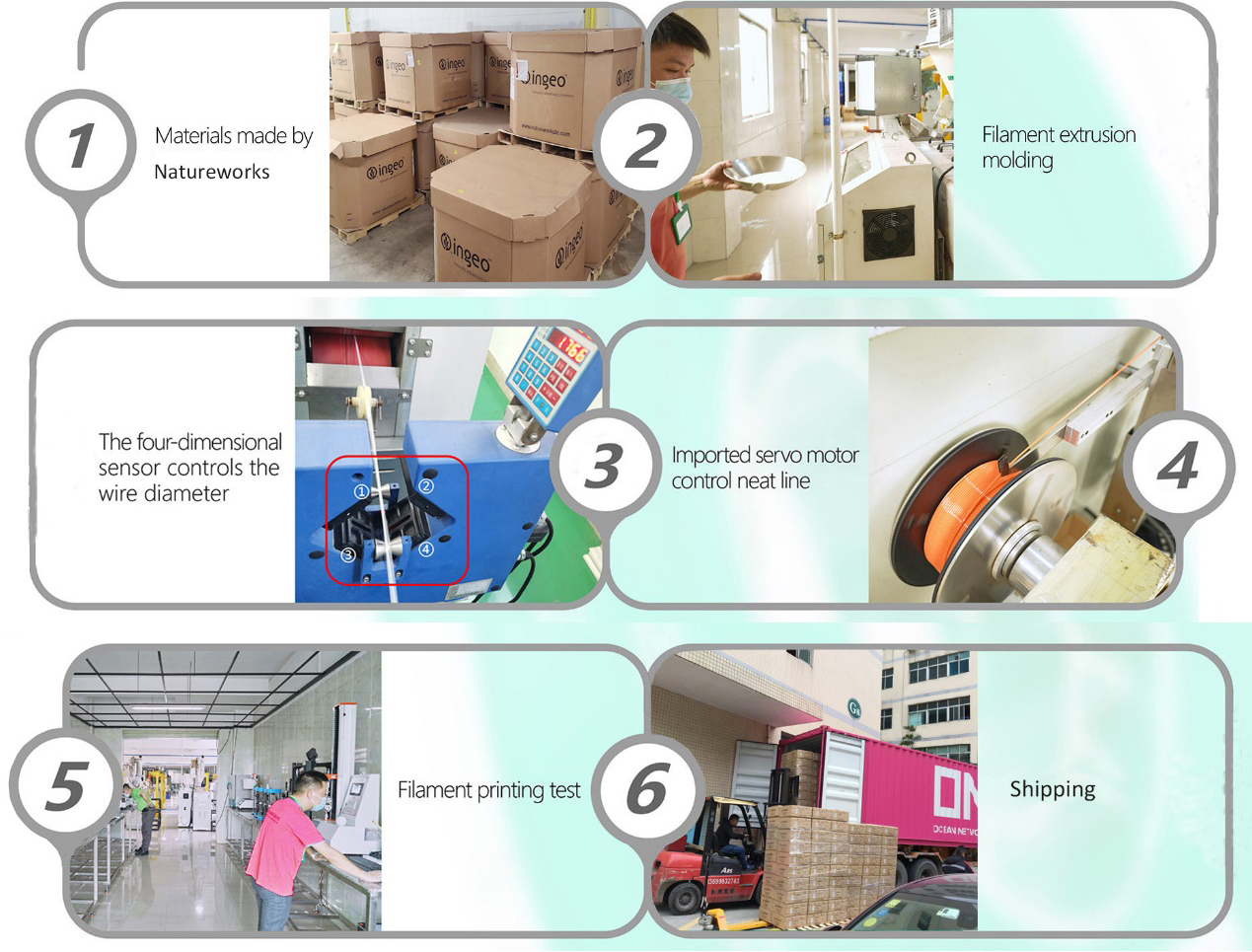

Factory Facility

FAQ

A : We are manufacturer for 3D filament more than 10 years in China.

A: Send Your Detailed Request→Feedback With Quotation→Confirm Quotation & Make Payment→Make Production→Production Test→Sample Test(Approval)→Mass Production→Quality Checking→Delivery→After Service→Repeat Order...

A: There's no minimum quantity ,you can buy any quantity. However, few in number, the unit price will be a little higher.

A: Depends on the type of product, warranty ranges from 6-12 months.

A: Western union, Paypal, T/T totally or 30% deposit before production, the balance before delivery. We suggest you transfer the full values at one time. Cause there is bank process fee, it would be a lot of money if you make twice transfer.

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 4.7(190℃/2.16kg) |

| Heat Distortion Temp | 52℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 14.5% |

| Flexural Strength | 65 MPa |

| Flexural Modulus | 1520 MPa |

| IZOD Impact Strength | 5.8kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

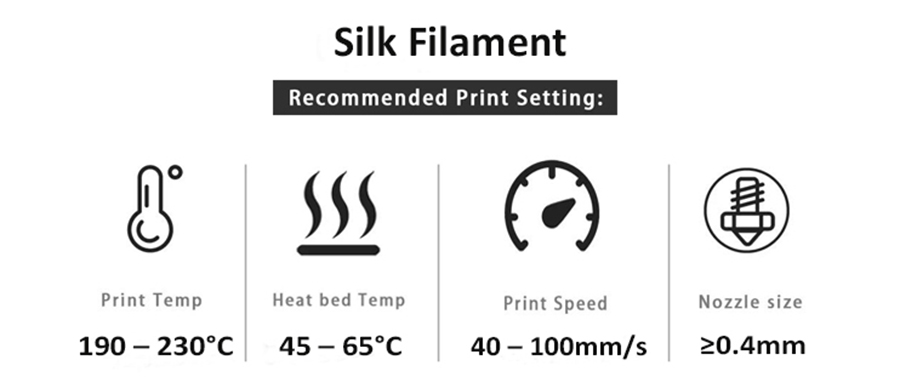

| Extruder Temperature(℃) | 190 – 230℃Recommended 215℃ |

| Bed temperature(℃) | 45 – 65°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | On 100% |

| Printing Speed | 40 – 100mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |