Torwell ABS Filament 1.75mm for 3D printer and 3D pen

Product Features

| Brand | Torwell |

| Material | QiMei PA747 |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 410m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 70˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV, SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

More Colors

Color Available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Nature, |

| Other color | Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent |

| Fluorescent series | Fluorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue |

| Luminous series | Luminous Green, Luminous Blue |

| Color changing series | Blue green to yellow green, Blue to white, Purple to Pink, Grey to White |

| Accept Customer PMS Color |

Model Show

Package

1kg roll ABS filament with desiccant in vaccum package.

Each spool in individual box (Torwell box, Neutral box, or Customized box available).

8boxes per carton (carton size 44x44x19cm).

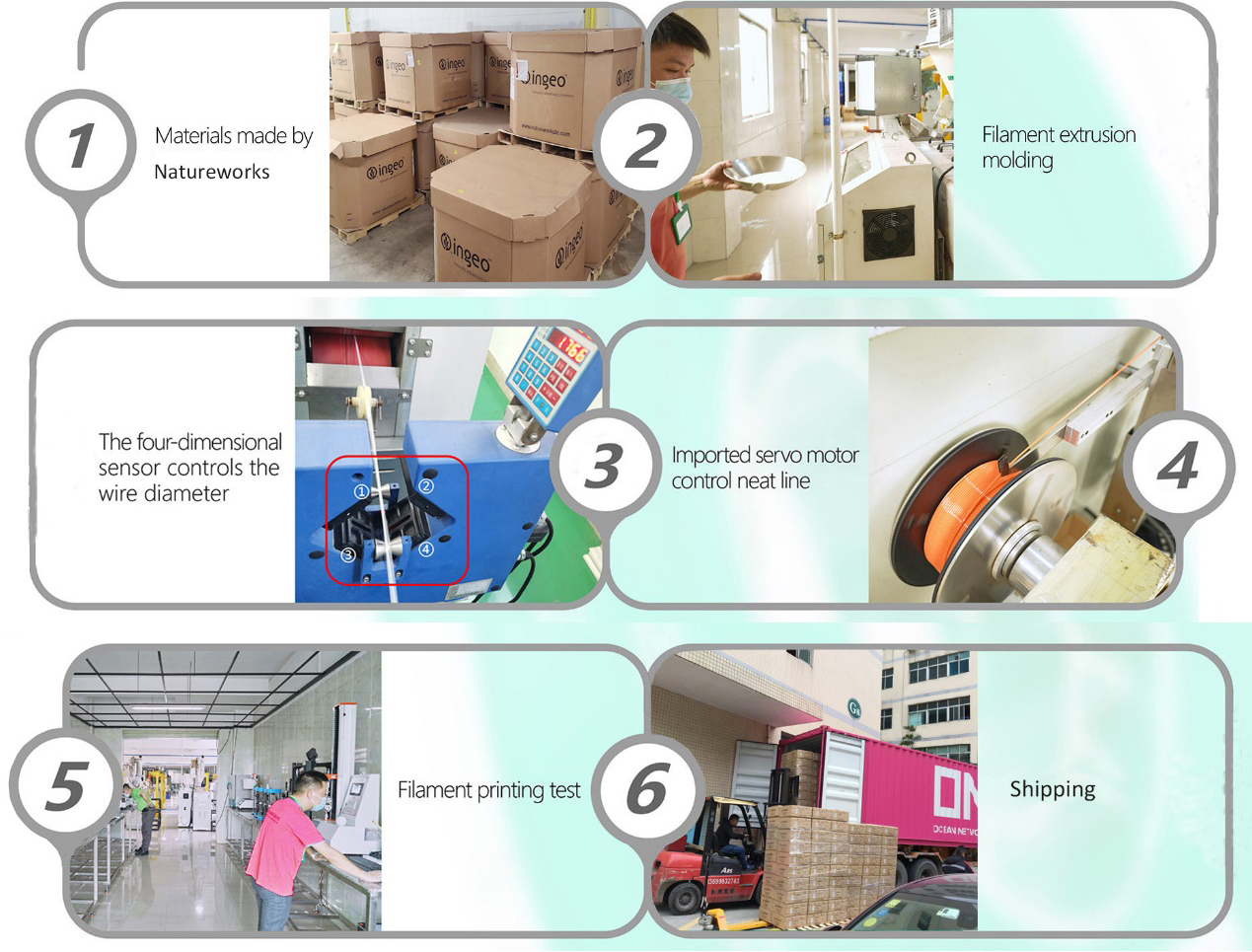

Factory Facility

Important Note

Please pass the filament through the fixed hole to avoid tangles after use. 1.75 ABS filament requires a heat-bed and a proper printing surface to avoid warping. Big parts are prone to warp in domestic printers and odor when printed is stronger than with PLA. Using raft or brim or reduce the speed for the first layer could help avoid warping.

FAQ

Why can't the filaments stick to the build bed?

1. Check the temperature setting before printing, ABS filaments have higher extrusion temperature;

2. Check if the plate surface has been used for a longtime, it is recommended to replace it with our new one to ensure a strong first layer adhesion;

3. If the first layer has poor adhesion, it is recommended to re-level the print substrate to reduce the distance between the nozzle and the surface plate;

4. If the effect is not good, it is recommended to try printing the draft before printing.

| Density | 1.04 g/cm3 |

| Melt Flow Index(g/10min) | 12(220℃/10kg) |

| Heat Distortion Temp | 77℃, 0.45MPa |

| Tensile Strength | 45 MPa |

| Elongation at Break | 42% |

| Flexural Strength | 66.5MPa |

| Flexural Modulus | 1190 MPa |

| IZOD Impact Strength | 30kJ/㎡ |

| Durability | 8/10 |

| Printability | 7/10 |

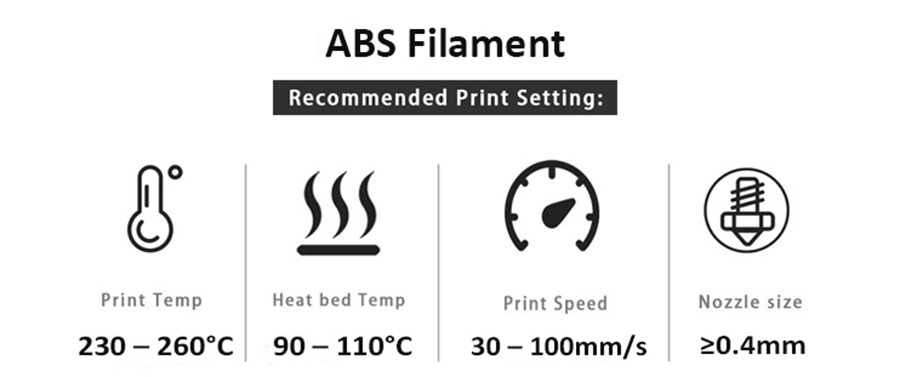

| Extruder Temperature(℃) | 230 – 260℃Recommended 240℃ |

| Bed temperature(℃) | 90 – 110°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | LOW for better surface quality / OFF for better strength |

| Printing Speed | 30 – 100mm/s |

| Heated Bed | Required |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |