Flexible TPU filament for 3D printing soft material

Product Features

| Brand | Torwell |

| Material | Premium grade Thermoplastic Polyurethane |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.05mm |

| Length | 1.75mm(1kg) = 330m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 65˚C for 8h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctnsealed plastic bag with desiccants |

More Colors

Color Available

| Basic color | White, Black, Red, Blue, Yellow, Green, Silver, Grey, Gold, Orange, Pink |

|

Accept Customer PMS Color |

|

Model Show

Package

1kg roll Silk filament with desiccant in vaccum package

Each spool in individual box (Torwell box, Neutral box, or Customized box avilable)

8boxes per carton (carton size 44x44x19cm)

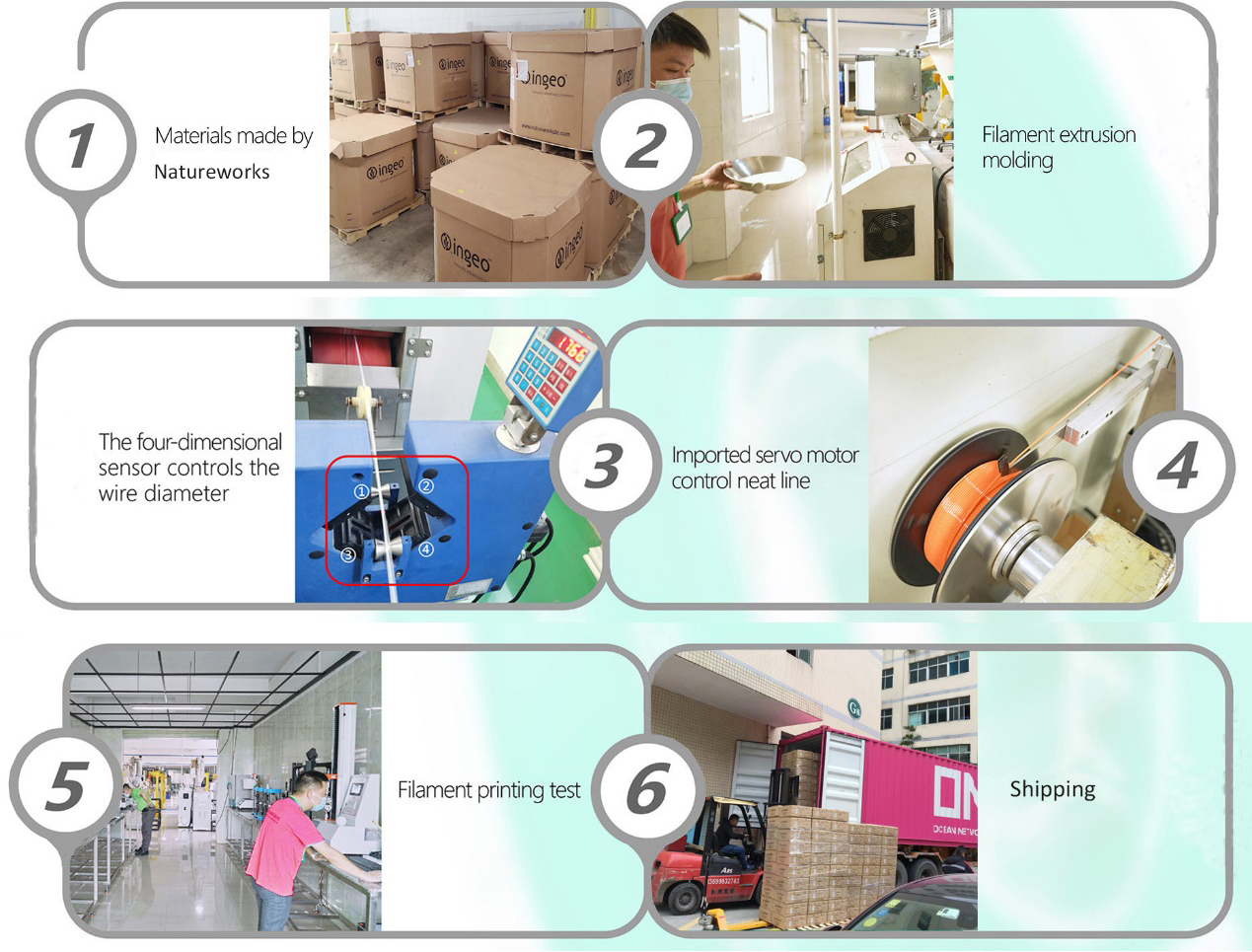

Factory Facility

More Information

Torwell FLEX is versatile and can be used in a wide range of 3D printing applications, making it the perfect choice for anyone who needs a flexible filament that can meet their specific needs. Whether you're printing models, prototypes or final products, you can rely on Torwell FLEX to deliver consistently high-quality prints that meet or exceed your expectations.

Torwell FLEX is an innovative 3D printing filament that will definitely change the way you think about flexible filaments. Its unique combination of durability, flexibility and ease of use makes it perfect for a range of applications from prosthetics and medical devices to fashion accessories. So why wait? Get started with Torwell FLEX today and experience the best 3D printing has to offer!

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 1.5(190℃/2.16kg) |

| Shore Hardness | 95A |

| Tensile Strength | 32 MPa |

| Elongation at Break | 800% |

| Flexural Strength | / |

| Flexural Modulus | / |

| IZOD Impact Strength | / |

| Durability | 9/10 |

| Printability | 6/10 |

|

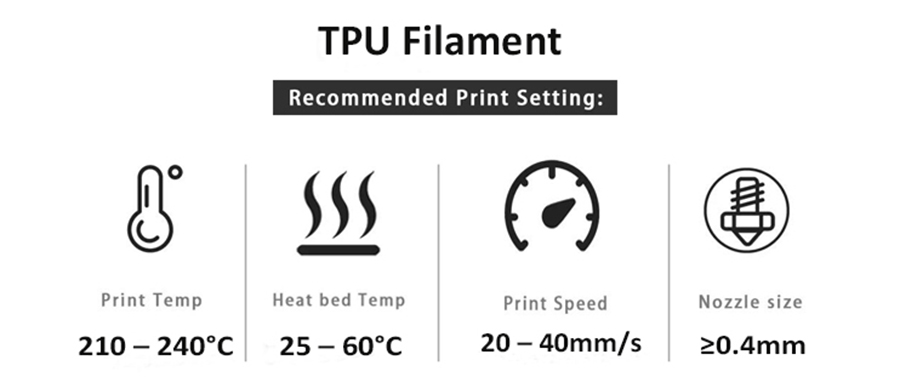

Extruder Temperature(℃) |

210 – 240℃ Recommended 235℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

20 – 40mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |